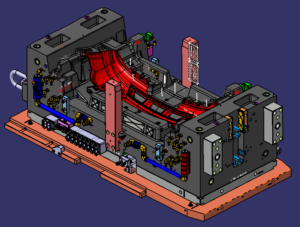

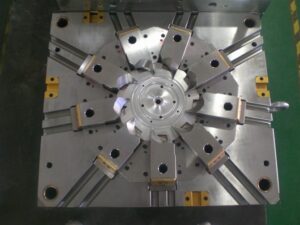

The bigger freedom between the ejector pin and the ejector through-opening not just serves to wipe out the sliding rubbing between the pin and the plate, yet in addition gives required slop to permit to misa lignment between the tomahawks of the ejector openings in different plates. The predetermined freedom ought to surpass the absolute stack-up of the openings’ positional resiliences over the form plates. Since ordinary boring resiliences are on the request for 0.25 mm, a diametral leeway of 0.5 mm should be adequate in most shape making applications. Moreover, a liberal chamfer should be given at the interface between the center addition and the help plate. As shown in china high-precision mould suppliers, this chamfer helps the controlling of the ejector pin from the help plate into the center addition during mold get together.

The definite plan of the ejector retainer plate is appeared in injection moulding services china. As appeared in Detail D, a counterbore is given in the ejector retainer plate to pull the top of the ejector pin(s) away from the splitting plane of the shape when the ejector framework is being withdrawn. To give leeway to misalignment of the places of the ejector openings, the counterbore is given a liberal resilience so the centerline of every ejector pin is represented by the mating of the pin with the reamed ejector opening in the center supplements. In the event that a shaped pin is utilized, the top of the pin is normally given a level as appeared in Detail E. An equal space and finding dowel are given in the ejector retainer plate to keep up the right direction of the formed ejector pin.

At whatever point conceivable, the shape architect ought to indicate a similar length and width of ejector pins to encourage form gathering and upkeep. On the off chance that distinctive ejector pins are utilized in the form plan, the shape fashioner and shape creator should make certain to key and name every ejector pin and coordinating area on the ejector retainer plate so the shape can be promptly kept up by the disintegrate. The form fashioner ought to consistently try not to plan ejector sticks that fluctuate just somewhat in their plan, since comparable pins may incidentally be viewed as exchangeable by the disintegrate.

The erroneous gathering of ejector pins may make harm the pins just as the restricting mold hole surfaces.

Ejector pins are normally hot manufactured and rotundly ground from hard prepares, (for example, H 13). Stubsequently, the pins are nitrided and cleaned to give an exceptionally hard and smooth surface for low wear and rubbing. Ejector pins are accessible from a few providers in standard measurements (going from 1 mm to 25 mm) and lengths (from 150 1mm to 500 mm). Ordinarily, form creators cut and pound standard ejector pins to the completed length and shape indicated in the shape plan. Be that as it may, ejector pins might be exclusively requested with changing alternatives including distinctive mate rials or surface treatuments, exact diarneters or lengths, strings for mating with the ejector plate, pads, grooves, and so forth While ejector pins are accessible in a scope of breadths and lengths, particularly long pins with little distances across should be dodged, The explanation is that such thin pins will in general clasp under burden. As appeared in plastic injection moulded components china, the stacking of an ejector pin relates to a section with the top end upheld by the drag of the ejector opening, and the base end stuck by the ejector retainer plate. On the off chance that the compressive burden become too huge, at that point the pin may bow or lock an obscure way.

This article is from http://www.chinainjectionmold.com/