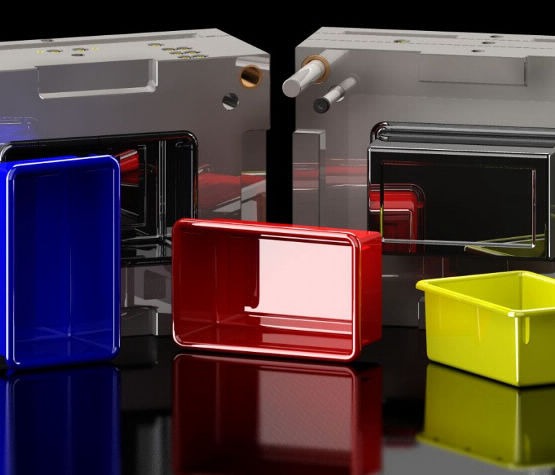

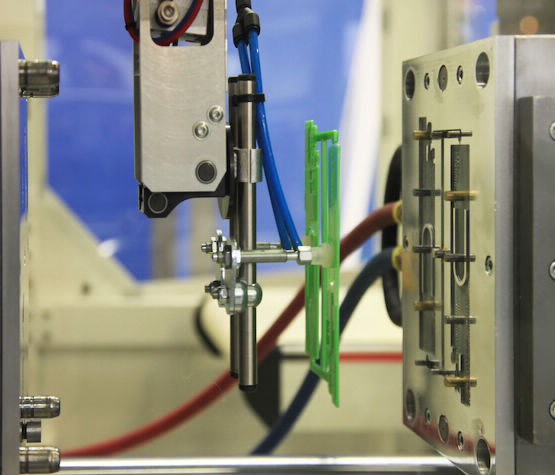

Injection Mould Manufacturer

As a leading high precision injection mold China maker, we supply top quality plastic tooling at very low making costs to serve hundreds of clients to shoot their headache troubles involving unstable quality, rough tolerance or long lead-time.

Thanks to the hard work of our experienced engineers and skilled technicians, over the past 12 years, we've successfully developed hundreds of plastic moulds totally comply to the Western tooling standards, for customer from a wide range of fields, which include medical, industrial tools, household appliances, automotive, and telecommunications.