Some cool high-quality plastic mould images:

What’s in my bag January 1, 2013 no Timbuk2 🙁

Image by Do8y

As much as it pains me, I had to replace my favourite Timbuk2 messenger bags. I have mentioned previously (www.flickr.com/photos/beorn_ours/7988163639/) that I had an elbow injury which had me get rid of the Laptop. At this time I was using the messenger bag because none of the below had happened yet:

– I noticed that the messenger bag was hard to put on without exerting strain on the not yet completely healed elbow (taking it off was no problem at all)

– some tasks/functions I took on at work required me to use some Mac OS X grade software and as much as I like my iPad, it simply did not have those (some of them requiring advanced file management and file encryption)

So I had to switch to a backpack – I found out that putting it on and off is much less of a strain on my elbow as I previously thought. Naturally, I bought a Timbuk2 backpack – a custom Swig Backpack. I had several major issues with it. Those are things that might not affect everyone who will use this backpack, but for me, they make the Swig unusable:

– the Swig is one size and fits a 15 inch MacBook Pro such as the one above, but getting it out trough the swig side opening is almost impossible – it is a real fight to do that and this is not the aim of this bag

– this backpack has VERY FEW organisation possibilities, the result being that all the things (and I really haven’t got that much anymore) are ending in a big bulk at the bottom of the bag making weight distribution impossible and creating a bulging lump on your back.

Looking at further backpack possibilities from Timbuk2 was not an option for me (delivery time of a couple of days was too long to wait as I had to lug the laptop already), although I found later that they do have something that would be better for my needs – Showdown Laptop Backpack. By then I have already given out quite a few bucks for Timbuk2 bags and did not want to risk it.

Then I went on a hunt for a good backpack – nothing in Zurich, Switzerland could answer any of my very specific needs. There were some really good bags and some interesting backpacks, but nothing as good in matter of organisation pockets as the backpack by Thule I found in the Apple online and then retail store. The product name is Crossover 25L MacBook Backpack – Black (www.thule.com/en/CH/Products/Luggage/DaypacksAndMessenger…) – do not trust the picture – it looks much more bloated in this picture than it is in real life as the producer was trying to show the total volume of, rather than to stress the really low profile this backpack has when on your back.

It has a vertical front pocket for my Kindle, sometimes my Moleskine is there for quick access to jot down notes while on my commute. Side pockets could hold a water bottle (half a litre bottles and even half a litre cans fit fine, although even my smallest SIGG bottle doesn’t, which is why I don’t carry any water currently), but I carry there keys, hand sanitizer and lip balm – the things I need immediate access to when out and about.

The front compartment has a mesh pocket for my wallet interdental brush and medicine tin. There is a very good plastic reinforced mesh pocket for my cables and SD cards.

The main compartment has got a good volume, but a narrow base so that it doesn’t sag when all the contents fall to the bottom. To allow you to distribute the weight vertically, without it all amassing at the bottom you have the side straps to compress the volume of the main compartment.

At the bottom of the laptop holder you have a very good padding so that you can put your backpack down without worrying what you’re doing to you laptop by doing so.

The shoulder straps are not padded and basically were the only thing that made me a bit hesitant when buying the bag, but they turned out to be very comfortable. There are a two carrying handles – one at the bottom and of course one at the top, in case you have the bag lying in some overhead compartment and you have to pull it out – you can do so no matter the position it is in.

NOW, we come to my favourite feature in this bag (after the reinforced mesh pocket and the vertical front pocket) – I call it the safe storage compartment, THULE calls it "Heat-molded, crush proof SafeZone™ compartment protects your sunglasses, iPhone, portable electronics and other fragile gear". It is really great for keeping this small piece of equipment that you do not want to be crushed or scratched by the rest of the things you cary. In my case what I put there are the Canon PowerShot SX260 HS camera and my brand new portable HDD LaCie Porsche design P9223 Slim 500GB.

So there, I hope all the above could be useful for someone who like me has a the need to transport a laptop everyday and has to ensure that putting this on and off one’s back is exerting as little strain as possible on both arms and back.

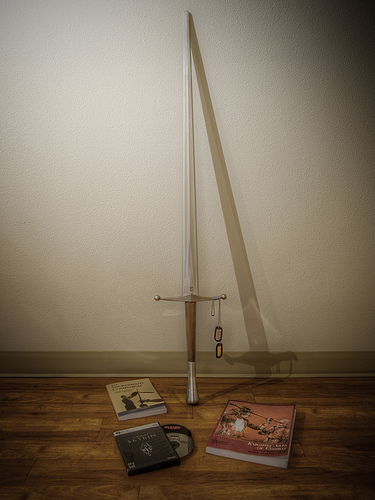

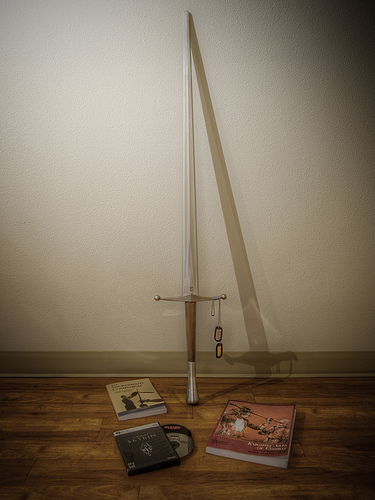

2014-11-29 – 001-007 – HDR – Longsword

Image by vmax137

My Rawlings synthetic longsword with a steel crossguard and aluminum pommel for weight. Dogtags for scale, books for learning, and Skyrim with some metal for motivation.

TL;DNR: All sword simulators from wood to blunts have their use in recreating the treatises. For me this synthetic longsword is safer and more realistic than the wooden waster that Arya was using in Game of Thrones but it’s more affordable and safer than good blunt steel sparring swords such as Federschwerts. At 0 USD for the price it’s a good sword simulator for beginners. More advanced students will find steel Feders to be a better option.

A Feder with a soft steel blade from Hanwei is about 0 USD but expect good ones from Albion and Regenyei Armory to start at around 0 USD and up. Finally I’m not a lawyer so please check the *written* local laws on whether transporting a covered sharp sword in public is legal or if a sword-shaped foam would be considered a weapon. In the United States city, county, and state laws can differ from each other.

Some German longsword action using Federschwerts and blunts:

www.youtube.com/watch?v=ohmLaZHStmI

Some Italian longsword action using Federschwerts:

www.youtube.com/watch?v=3WCgubznOlI

I’m not familiar with Talhoffer but the controversial John Clements performs this very interesting interpretation of half-swording:

www.youtube.com/watch?v=vi757-7XD94

Ok it’s going to be asked: yes you can grab sharp blades on some swords without cutting yourself if you avoid the edges or if pressure is applied to prevent slipping (but don’t do this without training by instructors!!):

www.youtube.com/watch?v=vwuQPfvSSlo

**Thank You Lindybeige, Skallagrim, and Scholagladiatoria**

I was reading a gaming forum on Guy Fawkes Day when the discussion of throwing knives behavior in the V for Vendetta movie led me to Lindybeige’s YouTube channel. While clips of his swing dance and wargame modeling were interesting the main draw was the discussion of weapons and various historical topics in bite-sized servings. Indirectly I found Skallagrim’s channel from related videos and topic searches where he assisted by his wife Cara introduced and explain basic historical combat in a very easy to understand manner. Scholagladiatoria’s videos often appear as well with even more in-depth discussions.

Though there may be disagreements in opinion they correspond with each other cordially by offering different viewpoints and are generally the three recommended channels when discussing historical European combat in English. So even though I was very aware of the New York Times video article on Longpoint 2014 back in September, thank you guys for showing that anyone can pick up a longsword simulator and have a go with it in about a week after watching a few videos.

I’m paying it forward with this long review for all those who don’t know about Historical European Martial Arts or HEMA.

Some Background

Let me preface this that I’ve just started and know probably as much as someone who have taken a brief introductory session. I have never held a museum sword piece or even fine replicas such as those from Albion although I have encounter wall hangers, poor heavy replicas, and other Sword-Like Objects.

Obviously there’s much more than longswords with Historical European Martial Arts or HEMA covering polearms, bows, and even WW2 bayonets. I decided that the longsword is a good place to start from as there are many treatises on it, is regarded as a good foundation to have that can be used for other arms, and is two-handed so the physical and mental barrier to entry is lower than say a one-handed sword and buckler. Plus it’s a friggen sword.

What makes HEMA part of but distinct from Western Martial Arts or WMA is the attempt to reconstruct as close to the sources as possible rather than add anything modern. Unlike a lot of other martial arts longsword living knowledge has been broken and this gap demands scholarly research and experimental archeology to verify each other. Interestingly Chinese two-handed sword techniques have been lost and reconstructed then adapted many times in history so what HEMA and WMA are doing isn’t a modern concept.

Normally I would start by checking with schools before getting equipment. But with schools some distance away my goals are simple solo technique drills mixed with historical research that will promote health, understanding of history, combat participant’s mentality, and philosophical enlightenment. Eventually sparring and classes will be required to progress but for now very basic strength training and research (along with poor foot work and plain wrong positioning) are enough of a preoccupation. Consistency first, then correction.

Obviously a waster or sword simulator for practice was needed, something that is a good approximation of a longsword and can handle contact sparring at an affordable price. Some sword simulators can handle the rigors of technique drills but not sparring; they’re not part of the discussion here. Trainers such as MBlades’ Swing are good for confined spaces but they’re not meant for sparring and there’s no way to practice half-swording techniques with them.

Wooden swords or wasters have a long historical pedigree and many still swear by them. They can be too light, bounce on contact, and are too dangerous during thrusts because they don’t flex. "Control!" people will cry, but as a beginner with no pell experience it’s better to err on the side of safety. I really like blunt steel Federschwerts or Feders – also a traditional training tool – but good ones are expensive. Feders from Albion and Regenyei Armory start at around 0 USD and up.

The expense increases further because of the protection required for inexperienced sparring. For those deciding on Feders sparring with against other Feders with the same blade hardness will prolong blade life for all participants. A steel Federschwert using an adjustable screw-held pommel will have to wait for now. Good blunt swords are closer in handling with sharps, but they flex more for safety (typically less than Feders but not always) and because they are blunt the edges do not stick. They are way beyond my budget and safety requirements anyway. Really, synthetic nylon swords are the only remaining option.

I’ve read very good things about Purpleheart Armoury’s Type III Pentti and Black Fencer’s Like Steel Waster Longsword V3. They were either a little too stiff or too expensive so I went with Rawlings. Everything’s that been mentioned have their place in recreating the treatises, it’s just that I’m deciding their usefulness to my situation.

Rawlings Synthetic Longsword Review

The parts were ordered from Purpleheart Armoury, an American company that imports Western Martial Arts and Historical European Martial Arts gear from Europe. Each component had to be selected separately and with everything except for the pommel made in the UK, I opted for a steel crossguard and a 5" extended aluminum pommel for weight and balance simulation. The cost for my build is 0 USD before tax and shipping.

My order needed a few changes but there were no replies to my emails. It wasn’t until the sword arrived that I was able to confirm that the changes were indeed applied so good on Purpleheart Armoury for fast processing and order changes, I just wish they would be more communicative in keeping their customers in the loop. The pieces came in a long rectangular box disassembled but assembly is easy enough that no instructions were required.

Blade

The 38" long blade has a lenticular geometry and while much thicker than the real article it has a moderate distal and profile tapering that aids in balance as well as safe sparring by reducing mass at the impact point. For further safety the tip and edges are well rounded with good flex at the last third of the blade for safe thrusting. All of this makes the blade too whippy during full speed swings but really metal sword simulators suffer from this to some degree as well although they’re much more resistant to taking a set or bend.

The 8" plastic tang encases a long metal screw rod that ensures all components will be held in place. The thread for the pommel came greased and for maintenance I recommend a water displacement such as WD-40 be used for cleaning off old grease and other contaminants followed by a very light coating of lubricant such as viscous machine grease.

Of note is that my blade flat had some excess molding material giving an appearance of dripping wax and stress marks. They’re not really bumpy and this sword isn’t a wall hanger so it’s not a problem but it may be for some. Another minor issue are rectangular mold registration points. The two on an edge may affect blade-on-blade impact but are easy to sand smooth. The one on the tip protruded enough to possibly damage fabric during impact and was carefully hand-sanded smooth after some effort.

The blade will take a set from true straight over time either from storage or temperature changes. It’s best to hang this point down by the crossguards if possible for storage and blade self-correction. For severe blade deformations a hot but not boiling water bath for a few minutes will help straighten it back, or modifying it as the case may be.

Crossguard

The 9.5" stainless steel casted crossguard has slightly upturned quillions that end in balls at the tips for safety. It’s held by compression from the pommel against the rubber grip so there is some very slight movement during severe impact at the guard but nothing that’s dangerous. Of note is that my crossguard came with minor cosmetic dings but again this sword is meant to be used. I’ve read from other people’s experiences that this guard can chew nylon blades after many enthusiastic sparring sessions.

The steel guard offers better protection for the hands and even during technique drills the added weight makes things a little more realistic so it’s recommended. The quillions aren’t thick enough to get in the way of fingering the guard, thumbing the blade, or simulate an overhand palm-up sword-throwing hold that would be at home in a judicial duel to settle a domestic dispute.

Grip

The longsword grip is sticky rubber that also compress against the crossguard with the aid of the pommel. It’s adequate but robust gloves such as leather work gloves are recommended against impact shock. Another reason is that when the grip gets wet dragging the palm across the surface will produce eraser-like particles of rubber. Wrapping grip tape may help.

It may not be apparent but the grip is oval at the crossguard and gradually becomes cylindrical towards the pommel which is great. A lot of fantasy swords get this wrong because the oval serves as a tactile indicator of where the blade is oriented. An imprecise cutting angle with a real blade can cause an ineffective bounce or can reduce the blade into a shower of sharp projectiles so this detail aids in forming good habits during practice.

The interior of the grip is sticky making it very difficult to slide over the tang and because of the imprecise fit there will be a noticeable tacky sensation as it shifts slightly during swinging. I used some talcum powder to eliminate it and to aid disassembly. Less then a pinch applied directly to the tang is all that’s needed – seriously, too much will increase movement of the grip that can cause premature wear.

Speaking of which I noticed white scratch marks on the rubber that I have no idea how they were made. When I tried to brush them smooth with my fingers the ridges from my finger prints made fresh white lines. This is the least durable component here but fortunately it’s also the cheapest to replace.

Update 2016-02-29

Some people have asked how to avoid abrasions when drilling bare-handed since the rubber grip unlike leather is a bit too grippy. I’ve used baby powder for a few months which worked really well before switching back to gloves because of stress marks on the palms appeared and general tenderness from drilling without shock protection. Other alternatives other people have suggested in forums include thin fingerless gloves and re-wrapping the grip. Rewrapping can be done easily with grip tape and will most likely prevent the waster from easy disassembly for travel.

Re-wrapping may also help with a slipping effect the loose grip gives when rotational forces are applied, typically during fast guard transitions that gives the waster a momentarily unsteady, mushy response. I’ve seen people made wood grips then wrapped in leather for their federschwert, something I’m sure the same can be done in a way that will allow disassembly for this synthetic waster.

Other possible solutions I haven’t seen tested are adding shims or apply thin tape onto the tang and mallet the rubber grip on.

The rubber grip itself has held up well. It’s very slightly looser than originally but I think it can make it through the rest of this year. The tang has rubber residues from the grip which occasionally needs to be cleaned off with isopropyl alcohol. Other than that some light application of baby power still work to prevent tackiness when rotational forces are applied.

Pommel

Historically pommel weight for balancing in real swords was a secondary function and in fact many were hollow. Here it’s a weight. I decided on the 5" extended mostly solid aluminum pommel (not the PHA or Pentti pommels) for my build instead of the nylon pommel for weight and balance. The two grip bevels and the border between the pommel’s round bottom and the adjacent angled facet were every so slightly sharp for comfort so liquid abrasive was used. The soft aluminum readily lends itself very well for polishing but it’s insanely easy to get scratches. Placing the sword on the ground pommel-first will guarantee gouges to the finish. Of great concern though is that repeated disassembly or looseness can increase the chance of stripping the pommel’s threads.

I found out later that many people prefer this extension for the length advantage it gives during a bout, an advantage that’s slight compared to fighter experience. For me it offers good simulated weight, better leverage, and more tactical options. It creates a very comfortable 13", three hand-width grip-space and overall the beveling was well done, making this a good option for someone who’s interested in some of the German longsword treatises.

For those that prefer a more lively handling snug grip that won’t get in the way with one hand use, something that offers little for an opponent to grab, or for those who decide to follow treatises that require a shorter two hand-width grip but still desire some weight stainless steel short pommels are also available.

Update 2016-02-29:

Aluminum is soft. Even if cared for the pommel will get dinged on a working waster. As a former aircraft maintainer aluminum will absolutely corrode in harsh environments. There’s no corrosion on the pommel so far but it’s never near salt water and food-grade mineral oil is lightly applied after cleaning and coating my montante waster.

Use

With a blade length of 38" and a total length of 52" the synthetic sword built is basically a Oakeshott Typology Sub-Type XVIIIb with a rounded tip. The weight is within historical ranges at about 3 lbs. but mass has been moved towards the guard to reduce tip impact force as a trainer. The point of balance is about 1" away from the crossguard center tip, a little close but again done for safety and is still within the historical range for some longswords.

From everything I’ve read and seen the thickness of the blade creates aerodynamic drag that makes it slower than a metal blade during a swing. The relative lightness allows it to accelerate quicker helping with directional changes so I suspect this nuance is what people are unconsciously implying when they say that synthetics are faster. I don’t know if it’s intentional but the tip creates an audible noise when a cut is done with the blade angled straight through the cutting path which can be extremely useful for training.

As mentioned during full speed swings the blade can get a little whippy but half-swording techniques and even Mordhau is still entirely feasible. Wearing padded work gloves I was able to easily finger the guard for greater point control. Thumbing the blade to assist in rotations or sticking the thumb up to protect it from an attack on the inside-line is also very easily done.

Binding is unrealistic of course as real sharpened swords will stick to each other very securely during edge-on-edge contact instead of sliding around. This is something that also affects dull metal blades. Some HEMA practitioners are testing 3M friction tapes, grip tape, and other alternatives on synthetic blades edges. The sword flats should remain slippy by being tape-free. From what’s been reported taping isn’t as good as sharp edge binds but it allows a much better binding and winding simulation than blunt swords. Skin contact at speed can create some bad abrasions so dress accordingly.

Whether synthetic or blunts for sparring it’s best to use like-with-like since blades can behave differently and can even damage each other at a rate that will outpace their intended life span. There are some very affordable sword simulators such as those from Cold Steel that are as balanced as clubs and the material is relatively rigid making them dangerous. Forget about using PVC pipes, they tend to shatter into sharp pieces and aluminum blades are not useful at all because their behavior deviates from steel so greatly.

Safety

I agree with the philosophy that increased risks adds to increased respect, but up to a certain point. I’m a beginner and we have modern knowledge and protective technology so I’ll leave the advanced fencing approaches to the experts. Since I’m soloing for now I might at most wear work gloves to prevent ripping off calluses. For sparring with synthetics the minimum protection recommended is as follows:

-A HEMA-rated face mask with back of head protection; Kendo and sport fencing masks can’t handle the extra force involved and offers no back protection for the head.

-A separate gorget throat protector will help prevent the crushed windpipes and broken collar bones.

-A chest protector, gambson or fencing jacket, preferably with the ability to insert a separate gorget underneath. People have found built-in throat protectors are not as effective as a separate gorget.

-Thick gloves to protect against broken fingers. Pay especially extra attention to side finger and finger tip protection.

-Male cup for the gents or female cup for the ladies.

Optional gear includes fencing pants, limb guards, joint guards, etc. This isn’t all inclusive and HEMA-rated gear are still being updated. Using wooden wasters and steel will of course increase the level of protection required compared to synthetics. Also armor remains a compromise between protection, mobility, and cost. Limbs still bend certain ways so many of the half-swording and wrestling techniques are very dangerous if done at full speed.

Using a pell to swing near-full speed then stopping just before impact or softening the impact can increase control and training partner survival rate. Generally more experience and familiarity with training partners will demand less protection, inexperience, increased speed, or unfamiliarity with opponents such as during a tournament will demand more. Wearing all of this gear can get extremely hot so hydrate to prevent heat stroke and make sure others do the same, especially in many events held in the open with no shade.

Legal

For transport a friend recommended a cloth Naginata bag for the blade that was on sale at E-Bogu. The sword will have to be disassembled of course but that should aid with peaceful intent if questioned by law enforcement.

I’m not a lawyer but according to the Seattle Municipal Code as long as the sword is covered for transport to or from an event or private location and it’s not being brandished it should be ok. Law enforcement will still have the ability to detain so be professional and if it’s a new club have insurance and uniforms. Otherwise follow Wheaton’s Law.

Conclusion

Those that are thinking of trying out HEMA will find this synthetic sword to be fairly good and is probably one of the best in it’s price category. It’s safer and more realistic than wooden waster sparring swords but more affordable and all things being equal safer than good blunt sparring swords and Federschwerts. Even though the metal parts more than double the price I would still recommend getting them if you’re in the same position of not being able to get a Feder.

But before rushing out to get this do ask the club that you’re going to train with and see what they recommend for gear. Otherwise like most things go with your budget and your ambitions. Thanks for reading, stay safe and have a good fight.

References

Basic properties of swords:

www.myarmoury.com/feature_properties.html

Some differences between sharp swords and blunts:

www.youtube.com/watch?v=T21uXihIZcI&list=PL_hVs5MjWFV…

Oakeshott Typology

www.albion-swords.com/articles/oakeshott-typology.htm

Sparring swords introduction:

www.hroarr.com/sparring-swords-introduction/

Why a sword feels right:

www.tameshigiri.ca/2014/05/16/why-a-sword-feels-right/

Resources

New York Times on Longpoint 2014:

www.nytimes.com/video/sports/100000003040466/inside-the-w…

HEMA Alliance club finder (doublecheck locations):

www.communitywalk.com/user/view/81443

Using different training tools and their characteristics for accurate reconstruction:

www.youtube.com/watch?v=QiEmcOCYElg

Video review of various Rawlings synthetic swords:

www.youtube.com/watch?v=mYBSVHA9drE

A more critical review of an older generation of this synthetic longsword:

www.hroarr.com/the-dave-rawlingsknightshop-synthetic-long…

How to get into Historical European Martial Arts:

www.youtube.com/watch?v=-3rHywjh1bQ&index=102&lis…

Longsword training tips:

www.youtube.com/playlist?list=PLMUtS78ZxryOMRve8RkM0vcrIK…

Sword Carolina has excellent solo training videos:

www.youtube.com/user/KASLKdF

Sword School is a supplement to fencing manuals by Guy Windsor:

www.youtube.com/user/swordschool

Flying with Swords (some good advice from experiance):

historical-academy.co.uk/blog/2014/12/26/flying-with-swords/

How to be comfortable wearing safety gear:

historical-academy.co.uk/blog/2015/01/16/how-to-become-co…

Seattle Municipal Code – Chapter 12A.14 – Weapons Control:

www.municode.com/library/wa/seattle/codes/municipal_code?…

Gear

Albion Swords (high quality and expensive):

www.albion-swords.com/

Black Fencer (their synthetic swords are preferred by some for their rigidity):

www.blackfencer.com/en/

E-Bogu (martial arts stuff for the Bruce Lees and Master Kens):

www.e-bogu.com/

Hanwei Federschwerts (CAS Iberia is importer, Hanwei is hit or miss do research):

casiberia.com/prod_list.aspx?q=feder

MBlades Swing compact sword simulator:

www.mblades.com/swing/index.html

Purpleheart Armoury (sword simulators, HEMA safety gear, etc.):

www.woodenswords.com/

Regenyei Armory (good quality potentially long wait, importer is HEMA Supplies):

www.regenyei.com/en_index.html

Books

The Swordsman’s Companion by Guy Windsor is a training manual that mainly follows the "Italian tradition" using Fior di Battaglia as a source. It’s a good manual for longsword beginners.

guywindsor.net/blog/books/the-swordsmans-companion/#sthas…

Sword School, supporting videos for The Swordsman’s Companion:

www.youtube.com/user/swordschool

Sigmund Ringeck’s Knightly Arts of Combat by David Lindholm and Peter Svärd is a training manual that mainly follows the "German tradition" mostly using Sigmund Ringeck’s Fetchbuch as a source. More of a supplement it covers sword and buckler, wrestling, polearms, and half-swording. Interpretations on mounted cavalry was not included.

www.paladin-press.com/product/Sigmund_Ringecks_Knightly_A…

Blogs

BWF – Box. Wrestle. Fence.

boxwrestlefence.com/

Encased in Steel

historical-academy.co.uk/blog/

Fight with All Your Strength

fightwithallyourstrength.blogspot.com/

Guy Windsor

guywindsor.net/blog/blog-2/#sthash.VDNBSuXh.dpbs

I don’t do longsword

hemamisfits.com/

The Hema-Tome

pterminiello.tumblr.com/

The HEMAists

thehemaists.com/

The Ring of Steel

theringofsteel.com/

Awesome YouTube channels

Lindybeige:

www.youtube.com/user/lindybeige

Skallagrim:

www.youtube.com/user/SkallagrimNilsson

Scholagldiatoria:

www.youtube.com/user/scholagladiatoria

Sword Carolina

www.youtube.com/user/KASLKdF

Update 2016-05-02:

Skallagrim has made an updated review and it’s negative for the Rawlings. Based on everything else consistently written or said by different people and clubs his comments are fairly on mark. The blade for my Rawlings longsword is nowhere as flexible as shown in the video because it’s not used for impact work on a pell, and the weight is closer to a steel federschwert than BlackFencer’s synthetic longswords. For my own use and considering Seattle city parks have legal restrictions dealing with anything that can be mistaken for an actual weapon I wouldn’t hesitate to get another one limited to solo drills.

www.youtube.com/watch?v=0D0R_DJhCW4

Untitled (In Memoriam, Jon Claremont)

Image by jay-chilli

From the photoblog Chillimatic

Posting a photo of a shop called "Party World" here is an odd way to memorialize someone. Bear with me, I’ll explain further down the page. Firstly a little on how I came to know about Jon Claremont and his work.

The service provider for my photoblog, Chillimatic, is called Expressions. Expressions won’t be rivalling Flickr any time soon and perhaps due to the small number of subscribers, or perhaps due to the good work of the people who run it, Expressions is a genuine ‘online community’ (prior to joining I had thought this phrase an oxymoron) brought together by a shared love of photography.

Some particularly high quality photoblogs are nestled alonside my own (frankly amateurish) site. Chief among these is a blog I discovered during my earliest nose around Expressions called ClaremontPhoto – Jon’s photoblog.

The aesthetic of Jon’s pictures was so different to that which currently prevails in photography that it was a shock when I first landed there. My eyes had become too accustomed to the diamond-sharp, perfectly colour-balanced images that digital technology has made possible to immediately accept photos taken with film cameras and developed at the local One Hour Photo. Jon’s snaps were often blurry and overexposed with no apparent colour scheme. His subjects rarely sat nicely in measured compositions.

Even when he was photographing the patrons of the shabby café-bars of Montemor-o-Novo, the town in Portugal where he lived – subjects who were in fact seated and immobile – there was always a touch of anarchy, a touch of humanity, his photos were alive. He once remarked in an e-mail to me that he didn’t do “pretty pictures”. He was wrong. His photos were beautiful, and in a way that all those diamond-sharp digital images could never be.

I started leaving comments on Jon’s site, he on mine, and our intermittent e-mail exchanges began. Just as one had to get past the aesthetic shock and look carefully at Jon’s photos to fully appreciate them so he looked carefully at others’. More than once he remarked on something in one of my shots that I hadn’t noticed myself. For this reason his words of encouragement were valuable to me; his appreciation was genuine.

Jon’s warmth of character was a further quality as apparent in his photos as his mails. Most of his shots were of the inhabitants of Montemor, a village lost in the countryside 40 miles to the east of Lisbon, a town not pretty enough for tourism nor rich enough for chain store homogeneity.

Similarly, Montemor’s inhabitants are neither charmingly rustic nor the neat, presentable Gap-clad men and women that the global economy has moulded. They’re a scruffy lot, spending their evenings sitting awkwardly on bar furniture, drinking cheap beer straight from the bottle, looking up slack-jawed at the football on the telly. In viewing Jon’s photos I was often reminded of Oscar Wilde’s famous aphorism “Work is the curse of the drinking classes”.

Most photographers, I think, would maintain a certain distance between themselves and such subjects, one that would translate into a mocking tone in their photos or a falsely reverent one: ostensibly honouring such ‘salt of the earth’ characters, covertly pitying them. Jon did none of that; the section at ClaremontPhoto compiling his ‘people’ shots is titled “Friends and Neighbours”. Quite right, they were not his subjects, he was one of them. The warmth and camaraderie so apparent in his photography were equally evident in his words to me.

Soon after I was first in contact with Jon he was appointed as Community Ambassador at Expressions, bringing to the members’ attention the work of other Expressions contributors, and continuing to offer words of encouragement and genuine appreciation to so many of us. He was very much the glue in our online community and I know that I am not alone in saying how greatly missed he will be.

I learnt of Jon’s passing on Friday and that same day Shanolyno, a fellow Expressions user, posted a comment on my photoblog. I mailed him to say thanks and told him the sad news. His words in reply voiced my own thoughts perfectly: “Seems strange to mourn for someone that I feel I know so well, yet I never met.”

I never met Jon Claremont either, I never even spoke to him and yet he touched me in some way, he inspired me, and I will miss him. For those that did know this clearly exceptional man, his family and friends, the loss must be very great indeed and my thoughts are with them.

So, the photo of “Party World”. It was taken in July of last year with a DSLR which I’d just bought, on the day I arrived in Sardinia, my holiday destination. During the preceding months I had spent much time on photography: taking photographs, tending to my website, reading about photography, viewing the work of others and occasionally exchanging e-mails with Jon.

Shortly before I left we had a quick exchange about Martin Parr, whose work we both admired. I wrote: “Regarding Martin Parr, yes the man is a genius, but I also kind of hate him because it’s become impossible to take photos in certain areas (supermarkets and seaside towns in the UK particularly) without thinking of his brilliant photos. He kind of owns all that now. If I ever find myself in a run down bar in Portugal and I’m unable to take photos because you’ve taken all the ideas and own that environment I’ll let you know.”

When I arrived in Olbia this throwaway comment had transformed into prophecy. Maybe it was the intensity of the sunlight (in Jon’s outdoor shots the walls and streets of Montemor appeared sun-bleached) or maybe it was the slightly tattered look that much of Olbia still has despite a recent influx of tourists courtesy of EasyJet, but I was unable to take pictures of the place, I saw Jon’s photos everywhere.

Thwarted in my attempts to take my own photos I decided to produce some imitation Claremonts. I turned the exposure up a notch to get the bleached look, switched the focus setting to “auto” to lose some sharpness and took a couple of shots of shop fronts which I imagined wouldn’t be out of place in Montemor. This shot was the most successful. I had intended to send it to him but, very regrettably now, never got round to it.

But "Party World", though? Surely not the best way to memorialize someone? Like I say – bear with me. This shop, despite its apparent banality, despite the cheap plastic knick-knacks it displays in the window, proudly proclaims itself “Party World” and this is in keeping with the meaning I read behind many of Jon’s photos. Despite the tawdriness of their surroundings; despite their shabby clothes; despite the cheap beer they’re given to drink every night; despite the fact that they live in a forgotten hinterland, held there just above the breadline; despite the fact that they’re old and working class (both characteristics that were once a source of pride but not so much these days); despite all this and much more, the people in Jon’s photos are mostly smiling. They’re happy.

My favourite of Jon’s photos is of a frail old man who sells lottery tickets from in front of a bar. According to the text accompanying the photo he’s there every week with the same patter, every week he has “the big one”. There he is – leaning against a rubbish bin, an expression of rapt wonder on his face as he eyes the little scraps of paper in his hand which, despite the 10-million-to-one odds, are going to bring in the jackpot. The Don Quixote of Montemor, he is both a fool and a hero.

As summations of the human condition go, it’s hard to beat. We are born into a world without purpose or meaning where there is but one truth: that one day, soon, we will be gone from it, obliterated. We have no chance; we are playing a machine we will never beat, which metes out suffering so much more than joy… And yet we still believe, holy fools that we are, that we’re going to land "the big one", that “A vida é uma festa!” Ladies and gentlemen, welcome to Party World.

So rest in peace, Jon Claremont, and thank you for showing me all this.

If you’ve read this far I hope you’ll click on the link for ClaremontPhoto. Many of his older photos (including the lottery ticket seller) have disappeared but there remain many photos of exceptional quality.