Check out these china assembly gear injection parts images:

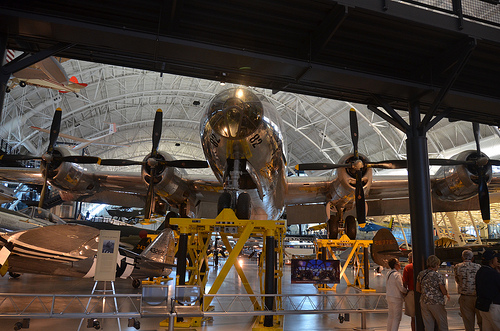

Steven F. Udvar-Hazy Center: B-29 Superfortress “Enola Gay”

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of World War II and the first bomber to house its crew in pressurized compartments. Although designed to fight in the European theater, the B-29 found its niche on the other side of the globe. In the Pacific, B-29s delivered a variety of aerial weapons: conventional bombs, incendiary bombs, mines, and two nuclear weapons.

On August 6, 1945, this Martin-built B-29-45-MO dropped the first atomic weapon used in combat on Hiroshima, Japan. Three days later, Bockscar (on display at the U.S. Air Force Museum near Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

Overall: 900 x 3020cm, 32580kg, 4300cm (29ft 6 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished overall aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish overall, standard late-World War II Army Air Forces insignia on wings and aft fuselage and serial number on vertical fin; 509th Composite Group markings painted in black; "Enola Gay" in black, block letters on lower left nose.