Some cool moulding services images:

Nottingham Council House – Old Market Square – lion

Image by ell brown

Close up views of details of the Nottingham Council House in Old Market Square.

The building is Grade II* listed building.

Council House, Exchange Buildings and Adjoining Shops and Bank, Nottingham

NOTTINGHAM

646-1/20/459 OLD MARKET SQUARE

04-FEB-1988 OLD MARKET SQUARE

(East side)

COUNCIL HOUSE, EXCHANGE BUILDINGS AND

ADJOINING SHOPS AND BANK

GV II*

Also Known As: 4, 6 AND 8, HIGH STREET, OLD MARKET SQUARE

1 TO 15, CHEAPSIDE, OLD MARKET SQUARE

YORKSHIRE BANK, 11, SMITHY ROW, OLD MARKET SQUARE

3, 4, 7 AND 8, SMITHY ROW, OLD MARKET SQUARE

Council House with offices and shopping arcade, and adjoining shops and bank, forming a rectangular island block. 1924-29. By T. Cecil Howitt for Nottingham City Council. Sculptural decoration by Joseph Else and mural paintings by Denholm Davis, with collaborators. Bank 1927, by A N Bromley of Nottingham for the National Provincial Bank.

MATERIALS: Steel frame with Portland stone cladding and dressings, and lead roofs.

EXTERIOR: Baroque Revival style. The windows are mainly glazing bar casements with bronze frames and panels. It has a granite plinth, with channelled rustication to the ground floor, a dentillated main cornice, and pierced balustrade. 4 storeys; 9 bays. The main west front has a projecting centre of 7 bays, reached by steps flanked by statues of lions, with round-arched ground floor openings and 4 bronze bracket lamps. Above, an octastyle Ionic portico in antis, rising through 3 floors and topped with a pediment containing relief sculpture. Under the portico, regular fenestration with metal framed glazing bar casements. There are blank end bays with round-arched ground floor openings. Rising above the centre of the building is a drum with Ionic colonnades and sculpture groups in niches at 4 corners. Above it is a large lead dome topped with an ornate cupola. The right and left returns are identical, with projecting central round-arched entrances rising through 4 floors. On either side, a 5 bay facade with ground floor shop fronts is divided by Doric pilasters. The upper 3 floors are divided by Ionic three-quarter columns in antis, and have regular fenestration. The right return has an additional single entrance bay towards the rear. The rear facade, to the east, has a central round-arched opening rising through 3 floors, with Ionic columns in antis under a pediment. There are single flanking bays with pendant lamps and round-arched ground floor openings. Above them are single windows on each floor. Exchange Arcade has at the crossing a glazed dome with paintings of historical scenes on the pendentives. There is a frieze with a lengthy inscription dated 1929. The main east-west arcade is 5 bays, has renewed shop fronts divided by square pilasters, and above, tripartite windows with moulded surrounds, also divided by pilasters. To the east is a 4 bay arcade, narrower and lower, defined by a stone arch, with cross casements in moulded surrounds. The eastern bay is 3 storeys and has 2 windows on each floor. The shorter north and south arcades have large transomed windows. The adjoining corner block to the south-east, dated 1922, is ashlar in a stripped Classical style. There are end bays with pilasters, an angled corner bay, and cornice and parapet. 4 storeys; 5 x 9 bays, with metal framed casements. The ground floor shop fronts are divided by plain pilasters, and above, there is regular fenestration, with a pedimented central window to each front. The adjoining bank, to the north-east, dated 1927, is by A N Bromley of Nottingham. It is ashlar, in the Baroque Revival style. It has a moulded granite plinth, rusticated ground floor, dentillated main cornice, pierced balustrade. It is 3 storeys plus attics; 5 x 9 bays, with glazing bar sashes to the upper floors and metal framed casements below. There are pediments and keystones to the first floor. The rounded corner entrance bay has a Doric door case with cornice and crest with supporters. Above is a single window on each floor. In the attic there is a cartouche date stone with supporters, under a broken scrolled pediment. The return facades have round-arched ground floor openings with keystones, and the upper floors are divided by Ionic half-columns. The end bays project.

INTERIOR: The Council House has a main entrance hall with marble panelling and Doric columns, and a curving marble staircase with pierced balustrade. The first floor reception hall has full height Ionic columns and a coffered ceiling. The dining hall has wooden panelling and pilasters, and a coved plaster ceiling. The Lord Mayor’s parlour and waiting room, members’ room and library have panelling. The Lord Mayor’s private room has C17 oak panelling from Ashton Hall, Birmingham, and the Lady Mayoress’s parlour has Adam-style decoration. The Council chamber has pilaster panelling and a coffered ceiling, and original seating and galleries. The bank has pilastered walls and 2 Ionic columns carrying a cross beam ceiling with a central domed skylight on pendentives. The bank fittings were renewed in the late C20.

HISTORY: Nottingham’s original Exchange Hall was built between 1724-6 on the site of the present Council House and Exchange Buildings. Consideration was given to the construction of a new town hall from the 1850s onwards, but it wasn’t to be until the early 1920s that the council had acquired the other properties in the Exchange block so as to be in a position to build on the complete site. The Council House, Exchange Buildings and adjoining shops and bank were built between 1926 and 1929. The official opening of the complex was on the 22nd May 1929. As Elain Harwood outlines in the Nottingham Pevsner Guide ‘Howitt’s initial scheme of 1923-4 anticipated recovery of the council’s buildings for University College. He therefore proposed rebuilding the Exchange as a superior shopping arcade, modelled on Milan’s Galleria Vittorio Emanuele, with top-lit arcades’. In an appreciation to its architect, T.C.Howitt, published in The Times shortly after his death in 1968, the Council House was described as ‘probably still the finest municipal building outside of London’.

SOURCES:

Scoffham E R, A vision of the City: the architecture of T C Howitt, (1992) 18-21; E. Harwood, Nottingham: Pevsner Architectural Guides (2008) 46-49;

J. Beckett and K. Brand, The Council House Nottingham and Old Market Square (2004)

REASONS FOR DESIGNATION:

* The buildings are considered to be an exceptional example of early C20 civic architecture which have undergone little significant alteration since their completion in 1929.

* The buildings represent a rare example of a Corporation commissioning its principal building from its own architectural service.

* The buildings retain their original principal interiors and almost all of their original fixtures and fittings all of which are of a consistently high quality.

* The special interest of the buildings is enhanced by the consistently high quality of the decorative art found throughout, including sculpture, murals, glass and plasterwork and by the range and quality of the building materials used in its construction.

* The arrangement of civic facilities and commercial buildings is unusual for local government buildings of this date and adds considerable interest.

This text is a legacy record and has not been updated since the building was originally listed. Details of the building may have changed in the intervening time. You should not rely on this listing as an accurate description of the building.

Source: English Heritage

Listed building text is © Crown Copyright. Reproduced under licence.

Lion

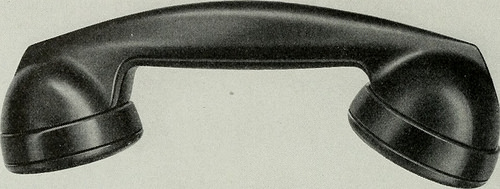

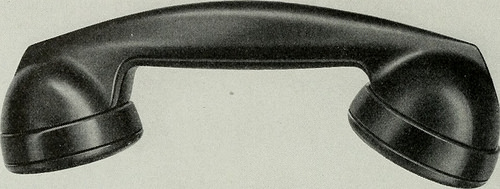

Image from page 513 of “The Bell System technical journal” (1922)

Image by Internet Archive Book Images

Identifier: bellsystemtechni18amerrich

Title: The Bell System technical journal

Year: 1922 (1920s)

Authors: American Telephone and Telegraph Company

Subjects: Telecommunication Electric engineering Communication Electronics Science Technology

Publisher: [Short Hills, N.J., etc., American Telephone and Telegraph Co.]

Contributing Library: Prelinger Library

Digitizing Sponsor: Internet Archive

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

orig-inally ground along the fin left by the semi-positive mold and thenbuffed. The operation was not only expensive but tended to grindoff a large portion of the surface of the handle. This removed theresin-rich surface and tended to expose the filler of the phenol plasticmolding compound, thus reducing the appearance life of the handle.The more recent product of the Bell System is being grooved alongthe die parting line. This removes the fin, a minimum of the resin- 490 BELL SYSTEM TECHNICAL JOURNAL rich surface and does not detract from the appearance of the handset.Automatic grooving machines were developed for this purpose. Figure4 shows a grooved handset handle. It has been found necessary to pay close attention to the design inorder that die parting lines, ejector pin marks, gate marks and the likewill appear at points where they may be readily eliminated by simpletrimming and grooving operations, or where they may be left withoutobjection to appearance or function of the part.

Text Appearing After Image:

Fig. 4—Grooved handset handle. General Test Methods and Requirements The most satisfactory test is one that can be applied to the finishedpart to measure the ability of that part to perform its function satis-factorily in service. This ideal is seldom realized, not only because ofthe difiiculty of defining the service requirements but of finding teststhat are wholly representative of service conditions. It is customary,therefore, to apply a series of tests whose sum total will approach theideal as nearly as practicable. Molded organic plastic parts aredifferent from parts made from most other materials in that themolding process may modify them and render them quite differentfrom the raw material. In the case of thermosetting compoundsthis is particularly true. Tests are in the main applied, therefore, to a molded part of repre-sentative specimen of the fabricated material. In the telephone plantthe items that are of most importance are strength, both transverseand impact, permanenc

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.