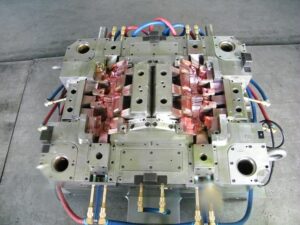

Klarm Mould, an oem/odm industrial mold design factory, can help for your mold design and minimizing. Here it shows plots the redirection of the mold and platens for the pressure dissemination. It is seen that the most extreme shape redirection happens at the focal point of the form cavity, with the center surface diverting 0.24 mm to one side and the hole surface avoiding 0.12 mm to one side. Accordingly, the liquefy pressure in the shape pit makes the surfaces separate by a sum of 0.36 mm (0.014 in).

This avoidance will cause any close by separating lines to open a comparable sum. Since this sum is a lot more noteworthy than the vent thickness (normally on the request for 0.02 mm), a lot of glimmering is normal. The form configuration should be improved to diminish this redirection.

The plotted shapes demonstrate that there is platen avoidance too. Shape fashioners and decays normally expect platens to be level and vastly unbending. While outside the extent of this book, platen diversion can be a critical issue. In oem/odm automatives injection molding design factory, the redirection of the fixed platen is around 0.04 mm, generally double that of the moving platen. The explanation is that the shape’s ejector lodging will in general exchange powers nearer to the sides of the moving platen so there is less applied burden and diversion in the focal point of this platen contrasted with the avoidance of the fixed platen.

The mold architect from china industrial injection moulding manufacturers can examine diverse shape materials and plans to decrease the form pressure and redirection. A survey of the material properties in Appendix B will uncover that harder materials, (for example, H13) can withstand a lot higher burdens than gentler materials, (for example, 1045 or QC7). Notwithstanding, the shape originator should know that all prepares have almost a similar flexible modulus, around 200 GPa. Therefore, the shape fashioner can’t change the avoidance by steel choice, but instead should depend on changing the calculation of the mold.

The least difficult strategy to diminish diversion is to expand the thickness of plates. As later investigation will show, this methodology is powerful since the solidness of the shape plates is identified with the block of the plate thickness. All things being equal, the rehashed utilization of huge and thick plates can bring about an excessively substantial and costly mold with a stack stature that restricts the accessibility of embellishment machines. Thus, the mold creator should try to limit the size of the form through fitting examination and cautious detail of plate thicknesses and backing structures, for example, uphold pillar and interlocks.

In mold plan, the term”plate” alludes to a kaleidoscopic or rectangular primary part with a length and width regularly more prominent than the thickness. The “face”of the plate for the most part alludes to the top and base surfaces of the plate that range the width and length headings. The”sides” of the plate allude to the four external surfaces of the plate that cross the thickness bearing. Shape plates are generally accessible from various providers in an assortment of sizes and materials. Plates can be furnished larger than average with a slight (1 mm) stock stipend, or finish ground to resilience on the request for +0.02 mm. This article is from http://www.chinainjectionmold.com