Some cool plastic injection part made in china images:

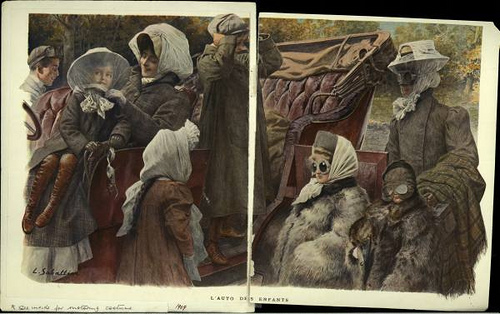

Oh the joys of the open road!

Image by brizzle born and bred

Timeline of motoring history 1940 – 2008

1940

Car production in Britain is put on hold as most factories go over to munitions production.

The German Luftwaffe destroys the centre of Coventry.

Oldsmobile and Cadillac offer the first fully automatic transmission.

Enzo Ferrari leaves Alfa Romeo to establish Auto-Avio Costruzioni Ferrari.

In Japan, Toyo Kogyo produces its first passenger car.

1941

Lord Austin dies aged 74

Louis Chevrolet dies aged 63. He is buried at Indianapolis, scene of his greatest racing victories.

Packard are the first car manufacturer to offer air conditioning.

Chrysler introduces the Fluid Drive transmission, a manual transmission with a fluid coupling instead of a clutch.

1943

American passenger car production falls to just 139 vehicles as war production requirements take over.

1944

Volvo focus on occupant safety with the introduction of a safety cage.

Louis Renault is arrested and imprisoned for collaborating with the Germans. He dies at Fresnes prison in ‘suspicious circumstances’.

Enzo Ferrari’s Maranello workshops are bombed and destroyed.

1945

2nd World War in Europe ends with Germany’s unconditional surrender to the allies on May 7th.

In receivership since 1939, Triumph is acquired by Standard.

Petrol rationing in Britain continues.

Henry Ford resigns as president of The Ford Motor Company, handing over to his grandson, Henry Ford 11.

French President Charles de Gaulle nationalizes Renault and the company’s name is changed to Regié Nationale des Usines Renault.

The newly elected Socialist government ‘encourages’ manufacturers to export half their output. To counteract the consequential development of an illicit black-market car buyers are required to sign a covenant preventing the sale of new cars for one year.

1946

Newly designed post-war models are launched by British car makers Triumph, Armstrong-Siddeley, Jowett and Bentley as the British Motor Industry celebrates its fiftieth birthday.

Petrol ration for British motorists is increased by 50 per cent.

Ford of Britain produce their millionth car, an 8hp Anglia.

Michelin patent the Radial-ply tyre.

In light of negative wartime connotations William Lyons changes the name of SS Cars Ltd. to Jaguar Cars Ltd and begins to focus on export markets.

Enzo Ferrari rebuilds his bombed workshops and begins work on the development and production of the Ferrari 125 Sport. The first Ferrari hits the road!

1947

Packard offers power seats and windows across their range.

Ettore Bugatti dies in Paris aged 66.

The American car industry celebrates its Golden Jubilee.

Henry Ford dies at the age of 84.

BMW engine and car designs are ‘acquired’ by Bristol and Frazer-Nash as ‘war reparations’.

David Brown, already successful in the British engineering industry, sees an advertisement in The Times offering ‘A high-class motor business, established 25 years’ and pays £20.000 to buy Aston Martin. He has already purchased Lagonda, having owned a Lagonda Rapide himself in the past.

A new name, Standard-Vanguard, is introduced to the British public

Instead of taxing cars based on the 1906 RAC horsepower formula a flat- rate system is introduced.

Enzo Ferrari’s 125 Sport wins its first race. The first of many Ferrari victories.

1948

The first motor show since the end of the war takes place at Earls Court.

Morris introduce the Minor family car, designed by Alec Issigonis.

Jaguar Cars Ltd. announces the XK120 sports car featuring low, streamlined body, an outstanding twin overhead cam 6 cylinder engine and a top speed of 120mph. Alongside it the elegant MK 5 saloon (sedan) replaces the pre-war model known by enthusiasts, though not the company, as the MK 4.

Citoen introduce the 2CV, reputedly designed to accommodate gentlemen still wearing their hats and to drive across a ploughed field without breaking a cargo of eggs!

The American motor industry builds its 100,000,000th car.

Ferdinand Porsche launches the Porsche marque by introducing the 356/2 as a no-frills sports car re-working of his war-time Volkswagen project.

Developed along the well proven lines of the Willys Jeep, Rover introduce the 4 wheel drive Land Rover.

Buick offer the Dynaflow fully automatic gearbox. This is essentially the automatic gearbox as we know it today,

1949

Michelin ‘X’ radial-ply tyres go on sale for the first time.

1950

British government ends petrol rationing but doubles fuel tax.

The new car covenant, introduced to prevent a black market in new cars is extended from one to two years ownership.

The UK’s former double purchase tax on luxury cars is halved.

Ford wins back its second place in the US sales league from Chrysler.

Automatic transmission becomes available on lower priced Chevrolet models.

Goodyear offers self-repairing tyres (tires).

60% of American families now own a car.

6,657,000 cars are sold in the USA.

Rover demonstrates the JET 1 the world’s first gas turbine powered car.

Ford engineer Earle S MacPherson designs the MacPherson Strut, a combination of spring, shock absorber and stub-axle which simplifies design and production and reduces costs.

Ford UK introduces Consul and Zephyr models.

In the USA, automatic gearboxes become more readily available – Chevrolet offer the Powerglide, Ford the Fordomatic and Merc-O-Matic.

Nash feature seatbelts in the Rambler. The promoted benefits are that they ‘overcome the problems caused when sleeping passengers fall out of their seats’!

1951

Porsche enters a 356 SL in the Le Mans 24-Hours and wins the 1100cc class·

Ferdinand Porsche dies aged 75.

Lotus Engineering Co founded by aeronautical engineer and competitive sports car driver Anthony Colin Bruce Chapman.

100mph performance becomes available at realistic prices as Triumph announces the TR and the Healey introduces their 100/4 sports cars.

Chrysler offer power steering and the M-6 Torque-Converter Automatic. They also spark a horsepower race with the 180 horsepower, 331 cubic-inch Firepower Hemi V-8 engine.

Kaiser introduces new safety features, a pop-out windshield and a padded dashboard top.

Jaguar introduces the prototype C-Type race-car, aimed at winning Le Mans.

1952

In the USA, sales of cars with automatic transmissions exceed 2 million.

Crosley ceases production.

Rival manufacturers Nuffield organisation (Morris) and Austin comes to an end with their amalgamation into the British Motor Corporation (BMC) with Lord Nuffield in the driving seat.

Mercedes shows the spectacular 300SL ‘gull wing’ sports coupe.

Packard offer power brakes.

The newly developed disk braking system, now available from Dunlop, is fitted to Jaguar’s C Types, enabling them to achieve 1st, 2nd and 4th places at Le Mans.

1953

As wartime austerity begins to fade in the United Kingdom, the availability of higher octane fuels allows higher compression ratios and improvements in engine performance.

Singer announces the SMX Roadster, Britain’s first plastic-bodied production car. Only 12 are made before the project is abandoned.

Britain’s New Car Covenant Purchase Scheme, originally introduced to prevent new cars being sold-on at a premium, is abolished.

General Motors Launch the Corvette, a radical glass-fibre-bodied roadster concept car featuring a wrap-around windshield and powered by a venerable straight six engine. Production is limited.

Porsche introduces the 550 ‘Spyder’ race-car with a triangulated tubular steel chassis, aluminium bodywork and a VW-based 4 cylinder ‘boxer’ engins. 550 Spyders dominate the 1500cc class at Le Mans and then the same class in the Pan Americana, Mexican road race.

1954

The 50 millionth General Motors car rolls off the production line.

All Buick, Oldsmobile and Cadillac models feature wrap-around Panoramic windshields.

Ford introduces overhead valves on its V8 engines in Ford and Mercury models.

Nash merges with Hudson to form the American Motors Corporation.

Studebaker merges with Packard.

GM reveals the 370 horsepower turbine-powered Firebird I concept car.

The two seat Ford Thunderbird roadster is announced.

Lanchester offer the Sprite with automatic transmission, still a rarity in Europe.

Having re-established production of the ‘Beetle’ with much help from British Army personnel, Volkswagen start to focus on generating export sales.

Tubeless tyres (tires) are now offered on all new American cars.

Jaguar Cars replace the XK120 with the XK 140, featuring a 190 horsepower engine, mechanical refinements and chrome trim. The new Jaguar D Type race-car is introduced at Le Mans without success.

1955

The revolutionary Citroen DS19 is introduced with a futuristic aerodynamic body, self-levelling hydropneumatic suspension, power steering and braking and automatic jacks.

McDonald’s opens its first drive-thru hamburger bar.

Chrysler launches ‘Imperial’ as a separates brand.

Kaiser goes out of business.

American car sales hit a record 7,915,000. Jaguar launch the MK 1 Family sports saloon (sedan) to broaden their market appeal. They also win at Le Mans with a much improved D-type.

1956

Fuel supplies are seriously limited by the Suez crisis, resulting in rationing in Britain and other European countries and an upsurge of interest in economical micro-cars for personal transportation.

U.S. car stylists begin to adopt tail fins and rocket-shaped tail lamps as science fiction and space rockets enter the American consciousness.

The Ford Foundation offers over ten million Ford Motor Company shares for sale to the public.

BMC commissions Pininfarina to styles its new models.

Lanchester comes to the end of the road as Daimler discontinues production.

Ford of America offers seat belts to a disinterested public.

The "McKenna Duties" on luxury imports are finally abolished.

Jaguar D Type wins the Le Mans 24 Hours for a second successive year.

The Porsche 550A Spyder, a modified version of its predecessor, wins the Targa Florio road race on its debut, beating much more powerful competitors. It goes on to ‘wipe the floor’ at virtually every appearance.

1957

The Lotus Elite (Type 14) is announced, featuring a revolutionary glassfibre monocoque construction.

Ford Motor Company introduces the Continental Mark II, priced at almost ,000.

The three millionth Mercury comes off Ford’s production line.

Packard and Chrysler offer pushbutton automatic transmissions.

Packard offers power door locks.

Chrysler offers an in-car record player.

80% of all new cars sold in America have a V-8 engine.

The American Congress approves construction of the 41,000 mile Interstate highway system.

The Nash and Hudson marques are discontinued by parent company AMC.

A new Fiat 500 is introduced featuring a rear-mounted vertical twin-cylinder air cooled engine.

Chrysler produce their ten millionth Plymouth.

The new Ford Skyliner features a retractable hardtop, a ‘first’ for a production car.

Ford introduces the Ranchero pickup.

Chevrolet, Pontiac and Rambler adopt fuel injection.

66% of all cars purchased in the USA are bought on extended finance.

Jaguar introduce the XK 150 and a D Type wins the Le Mans 24 Hours for a third successive year.

1958

Work starts on the Ml ‘London to Birmingham’ Motorway, the UK’s first.

Roads around London are governed by a new 40mph speed limit.

To celebrate the fiftieth birthday of the Model T, Ford re-assembles a 1909 example.

Ford produce their fifty millionth car.

The revolutionary glassfibre Lotus Elite (Type 14) enters production. With all-round independent suspension and a 1,216 cc overhead cam Coventry Climax engine it has spectacular handling and is capable of 118mph! In spite of its success as a racecar Lotus will loose money on every one built.

With controversial styling and sophisticated features, the Ford Edsel is launched to a luke-warm reception.

Chrysler builds its twenty five millionth vehicle.

Packard production comes to an end.

The Austin-Healy ‘Frogeye’ Sprite is introduced.

The new chairman of BMC is Sir Leonard Lord.

A record one million cars are produced in Britain.

Toyotas and Datsuns are imported to the United States for the first time.

The Ford Thunderbird becomes a four-seater ‘personal luxury’ car.

American car sales drop by 31% due to an economic recession.

C F Kettering, inventor of the electric starter and Ethyl-Leaded Gasoline dies aged 82.

Porsche introduce the "RSK" Spyder, or Type 718 which continues to win class and outright honours in the hands of such drivers as Dan Gurney, Wolfgang von Trips and Jo Bonnier.

A fascination with the impending space-age inspires Cadillac to begin giving its new models fins and rocket-shaped taillights.

1959

UK Government reduces Purchase Tax on new cars from 60 to 50 per cent.

Triumph introduce the Michelotti styled Herald, featuring all round independent suspension.

Lea Francis go out of business.

NSU announce that they will build Wankel rotary engined cars.

Dutch manufacturer DAF begins car production, using the Variomatic belt-drive automatic transmission.

The M1, Britain’s first motorway is opened by The Right Honourable Ernest Marples, minister of Transport.

British Motor Corporation introduces the Morris Mini-Minor and Austin Se7en variants, built on separate production lines at Cowley, Oxford and Longbridge, Birmingam to a revolutionary compact design by Alec Issigonis. Whichever brand of ‘Mini’, it features a rubber-cone suspension system and a gearbox built into the engine, beneath the crankshaft. Perhaps the Mini’s most significant contribution to the packaging efficiency of modern front-wheel-drive cars is its transversely mounted engine.

Jaguar launches the MK II family sports saloon (sedan) to great acclaim.

The Ford Anglia arrives. It is a small family car with conventional mechanical layout. Its unusual feature is a reverse-slope rear window, which ensures good headroom for rear-seat passengers.

Studebaker introduces the Lark, a compact car intended to compete with European imports.

An Aston-Martin DBR 1, driven by Caroll Shelby and Roy Salvadori wins the Le Mans 24 hours.

1960

Eighty percent of United Stated families own at least one car.

The UK Daimler Company becomes part of Jaguar Cars.

The Japanese car industry manufactures 200,000 cars.

The Ford Anglia l05E is introduced with a four speed gearbox and a raked back rear window.

OPEC (The Organization of Petroleum Exporting Countries) is formed to give the oil producing countries more power over crude oil prices.

The millionth Morris Minor leaves the production line, one of a series of 350 painted in a celebratory shade of lilac with white leather upholstery.

Jaguar Cars Limited buys Daimler and begins to offer ‘badge engineered’ Jaguars.

1961

The Cortina Mk I is introduced by Ford of Britain.

BMC introduce the Morris I IOO featuring a revolutionary ‘Hydrolastic’ suspension system.

The ‘MOT’ test is introduced by Ernest Marples, requiring that all cars over 10 years old are subjected to an annual test.

BMC chief, Sir Leonard Lord becomes Lord Lambury.

Commercial vehicle producers Leyland Motors acquire Standard Triumph and AEC.

Porsche introduce the W-RS Spyder race-car with its well-proven flat four power unit.

1962

Chevrolet introduce the Nova, a compact car with plain styling and 4 or 6 cylinder engines, designed to offer economical family motoring.

Ford UK introduces the Consul Cortina, an attractive medium-sized family saloon, powered by an 1198cc OHV engine. (The ‘Consul’ is dropped very quickly). Though launched as a two-door, a four-door body becomes available within a few months.

The W-RS Spyder, now powered by a 2.0-litre flat-eight engine, continues to build Porsche’s racing prowess by winning everything in sight.

1963

The Leyland Motor Corporation formed under the chairmanship of Sir Henry Spurrier.

Ford’s Cortina DeLuxe is now available with a 1498cc engine and also as high-performance Lotus model featuring a twin-cam engine and major suspension modifications.

Lord Nuffield dies aged 86.

The Hillman Imp is unveiled to compete with the BMC Mini. It features a light-alloy 4 cylinder, 875cc slant-4 engine, originally developed by Coventry Climax to power fire pumps. Manufactured at Linwood, a new Scottish production plant, this is the first car since the 1931 Arrol Johnston, to be made in Scotland.

NSU announce the Spyder their first car to use a Wankel engine.

Rover introduces the 2000 P6 saloon which wins them the European Car of the Year Award.

In Italy Feruccio Lamborghini Automobili founded in Sant’Agata near Bologna. The debut of the prototype 350 GTV takes place at the Turin Motor Show.

Porsche’s W-RS Spyder continues its winning ways at Le Mans and the Nurburgring.

1964

Triumph launches the 2000 family saloon.

The Ford Mustang is ‘released’ to great acclaim and achieves sales of more than 500,000 in its firs 18 months.

Following many years of crippling strikes at its British Light Steel Pressings Ltd factory, the Rootes Group sells a controlling interest to Chrysler.

Despite continuing disinterest, front seat belts supplied as standard in all American cars.

Having resigned his position after just 4 months in charge of The Leyland Motor Corporation Sir Henry Spurrier dies.

Porsche’s W-RS Spyder wins further season championships in the hands of Edgar Barth, before final retirement.

1965

BMC’s intended merger with the Pressed Steel Company is subjected to a report by the Monopolies Commission.

The British government introduces a 70 mph maximum speed "as a four month experiment" which is still with us today.

An automatic transmission, specially designed by AP is available to Mini buyers.

Rolls Royce’s launch Silver Shadow its first unit constructed car.

Ralph Nader publishes his book ‘Unsafe at Any Speed’ exposing safety standards severely compromised by USA manufacturers’ cost constraints. The rear-engined Chevrolet Corvair receives Nader’s particular attention.

1966

Jensen FF sports coupe is launched, featuring Fergusson’s four wheel drive system, Italian styling, a powerful V8 engine and anti-lock brakes.

British Motor Holdings is created by merging The Jaguar Group (Jaguar, Daimler, Guy, Coventry Climax, Henry Meadows) with BMC.

Ford UK update the Cortina with smoother, but boxier styling.

Largely as a result of Ralph Nader’s expose of the American Motor industry the U.S. Congress passes a rigorous auto safety act. Rear seat belts now supplied as standard equipment in all cars sold in the USA.

Peugeot and Renault agree to establish a partnership organisation, La Francaise de Mecanique, to manufacture common mechanical parts.

Sir William Lyons retires as the Managing Director, becoming Chairman and Chief Executive as Jaguar Cars Limited and the British Motor Corporation Limited announce the merger of the two companies.

1967

Panhard, France’s oldest car maker is disolved by its owners Citroen.

NSU produce the first series production passenger car to be powered by a Wankel engine, the Ro80.

Rover and Alvis are absorbed into the Leyland Motor Corporation.

Ford UK introduce the crossflow engine to their product range in 1300cc and 1600cc capacities.

Ford UK and Ford of Europe start to co ordinate development and production programmes to increase commonality of design and component use.

1968

Ford introduces the Escort range, including a high performance ‘twin-cam’ engined version.

The largest car company in British history is formed as British Motor Holdings merges with Leyland Motors to create British Leyland Motor Corporation.

Rover offers the Buick-based V8 in the P6 body-shell to create the 3005, later re-named the 3500.

As bitter strikes cripple industry Renault lose production of I000,000 vehicles.

Volkswagen introduces the 411 or ‘Variant’. Based on an extended ‘Beetle’ floor-pan it features a contemporary body-style and 2 or 4 doors. An estate (station wagon) version is also available.

Citroen buys Maserati, primarily, to take advantage of its engine know-how. Their forthcoming SM coupé will be powered by a Maserati V6 engine.

David Brown is knighted.

1969

Volkswagcn take over Audi.

Jaguar launches the XJ6.

The new British Leyland organisation introduces the Austin Maxi. Sir Alex Issigonis’s last project, in spite of its outstanding practicality, its boxy styling, sparse interior, lack of power and ‘notchy’ five-speed gearbox attracts criticism.

Renault and Peugeot start production of common components as a result of their 1966 agreement, at Douvrin, near Lens in Northern France.

Enzo Ferrari sells 50% of Ferrari’s share capital to Fiat.

1970

Land Rover launches an entirely new concept. The Range Rover is a luxury off-road car and, as an immediate sales success it points the way for rivals, laying the foundation for a whole new market sector.

Citroen launches two new aerodynamic models, the GS family car and the Masserati-powered SM sports saloon.

Italian styling house Ghia of Turin is acquired from Alessandro de Tomaso by Ford.

Mercedes build the C III experimental car to act as a test-bed for future road-car developments. Featuring dramatic aerodynamic styling and powered by a triple rotor Wankel engine developing 280bhp, it achieved a top speed of 160mph.

Japan’s monthly production output of 200,000 cars, makes it the world’s second biggest motor manufacturer.

Volkswagen reveals the K70, their first water cooled model.

Kjell Qvale, Norwegan born head of the ‘British Motor Car Distributors’ in San Francisco, takes over Jensen Motors.

The Chrysler 160/l80 range is launched at the Paris Salon.

The General Motors’ ‘family’ come together from all parts of the globe, under the leadership of Opel, Germany, to begin a project which will result in a ‘World Car’ to rival the success of the VW beetle. For Opel it will result in the Kadette C, small family car. Internationally it becomes known as GM’s ‘T Car’.

1971

Jensen ceases production of the four-wheel-drive ‘FF’ sports-car, but continues with the two-wheel drive ‘Interceptor’ version.

Morris Minor production finally comes to an end.

Peugeot and Renault join forces with Volvo to form a new joint-venture organisation. PRV will design and produce V-engines at their Douvrin production plant.

Mercedes preview the C111-2 at the Frankfurt Motor Show. Once again a test-bed vehicle it features a four-rotor Wankel engine rated at 350 bhp which took the car to 180mph.

Aston Martin’s financial performance causes difficulties, prompting the David Brown Group to sell to financiers. The DBS stays in production.

Jaguar reveals their VI2 production engine, making it available in an enlarged E-type as well as XJ6 and Daimler sedans. This makes them one of only a handful of manufacturers who have ever offered this configuration on a production basis.

Maserati introduce the Bora.

1972

A record l,900,000 cars produced by British motor industry in this year.

The success of Japanese cars becomes evident when Datsun becomes the second biggest importer of cars into Britain.

Maserati introduces the Merak.

Lotus Esprit mid-engined concept car shown on Giorgio Giugiario’s Ital Design stand at the Turin Motor Show.

Sir William Lyons retires as chairman of Jaguar, exactly 50 years after forming the company. Labour relations and production quality problems beset the whole British Leyland organisation, of which Daimler-Jaguar is a significant part.

1973

The Arab-Israeli War causes fuel supply problems and steep rises in pump prices for motorists throughout the world and the realisation that oil is a finite resource. The OPEC organisation becomes more powerful. In Britain motorists queue for petrol and speeds are restricted to 50mph to conserve national stocks and consumption.

Ford opens Bordeaux plant to manufacture automatic transmissions.

Volksvagen ‘Beetle’ production beats the Model T’s record.

Chevrolet offers airbags in some models as a reaction to a rise in fatal car accidents in the USA.

Alfa Romeo introduce the Alfasud, a small family car featuring front wheel drive, a flat-four ‘boxer’ engine, nimble handling and a bonded-in windscreen. The car is made in a new purpose built plant near Naples in Southern Italy – ‘sud’ being Italian for South.

The Bertone-styled Maserati Khamsin is launched into a tough sales environment.

The first fruits of the GM ‘T Car’ project appear in Brasil, with the launch of the Chevrolet Chevette and in Germany with the Opel Kadett C. Although superficially different all T Cars share the same mechanical configuration and many significant components.

1974

E. L. Cord dies

Gabriel Voisin, aeronautical pioneer, industrialist and car manufacturer dies.

The last of 11,916,519 VW ‘Beetles’ to be built at Wolfsburg, leaves the production line.

The VW Golf, a completely new water-cooled, front wheel drive model becomes and instant sales success and Karmann start production of the Scirocco sports coupe version. Both cars styled by Georgetto Guigaro.

Peugeot takes over Citroen to form PSA.

Plans for the Chevrolet Vega to be powered by the repeatedly delayed outcome of General Motors’ Wankel rotary engine project are abandoned and production continues with an alloy block/iron head 4 cylinder unit.

As a result of the previous year’s the fuel crisis, American sales of large-engined cars have slumped and manufacturers start to look at ways of improving fuel econonmy.

Ford begins research into the Stirling ‘hot air’ engine but having made considerable progress, as fuel prices drop back the urge to take the project all the way to production diminishes.

In spite of one million 127s leaving their production lines Fiat find themselves in deep financial difficulties.

The last E Type Jaguar leaves the Coventry factory.

The Douvrin-built PRV V6 engine appears for the first time in the Volvo 264 and soon after in the Peugeot 504 Coupé and Cabriolet models.

In an attempt to cut fatalities in the United States the maximum speed limit is reduced to 55 mph.

1975

Production of the Ford Escort MK1comes to an end.

Ford introduce the Escort MK2 with a squarer body style.

In America VW launch the Golf as the Rabbit.

Rolls Royce unveil the Camargue with Italian styling by Pininfarina, hand- built on the Silver Shadow floor pan at their Mulliner Park Ward coach-building division. Priced at £29,250, it is the first car in the world to feature completely automatic split-level air conditioning and the first Rolls Royce to be designed in metric dimensions.

Porsche announce the 911 Carrera Turbo.

Chrysler UK, in financial difficulties is propped up by the British Government. The introduction of the French built Alpine brings in vital sales.

Volvo takes a majority shareholding in Holland’s DAF car and truck manufacturer.

The Douvrin-built PRV V6 is introduced in the Peugeot 604 and Renault 30 TS models.

Citroen replaces the DS21 with the CX which is voted European Car of the Year.

British Leyland, struggling against a tide of strikes and a poor reputation gets an injection of £200,000,000 from the UK Government.

Jaguar launch the XJS to replace the E type. Due to stringent American crash regulations earlier plans to include a roadster in the range have been dropped.

Lotus Cars start production of the new mid-engined Esprit and confirm their move up-market with front-engined Eclat.

All American cars now come with catalytic converters in the exhaust system in an effort to cut air polluting emissions.

Citroën pulls out of Maserati, leaving Alejandro De Tomaso and GEPI to come to the rescue a few months later.

VW introduce the Polo, the third of their ‘new generation’ cars.

The UK gets its own version of the GM T-Car, the Vauxhall Chevette. A unique aerodynamic ‘droop-snoot’ front-end, designed by Vauxhall Chief-Stylist, Wayne Cherry complements the neat hatch-back body tub.

Australia launches its version of the ‘T Car’, the Holden Gemini, in 4-door saloon (sedan) and stylish coupé versions.

1976

The Chrysler Alpine voted European Car of the Year.

The Renault Alpine A310 sports-car is launched with a rear mounted PRV ‘Douvrin’ V6 engine.

Ford’s first front drive car, the Fiesta, announced.

The Golf GTi debuts at the Frankfurt International Motor Show establishing a new market sector later known as the ‘Hot Hatch’.

Rover launch the 3500 ‘SD1’ a roomy saloon with Ferrari Daytona inspired styling and the ex-Buick alloy V8 engine.

VW introduce a small diesel engine to the golf range.

Mercedes reveal the C111-3. Where its two predecessors had been powered by Wankel rotary engines, this one has a 5 cylinder turbo-charged/inter-cooled Diesel engine producing 180 bhp. At Nardo test track on June 12th, at an average speed of around 150mph, the C111-3 either establishes or brake a total of 16 world speed and endurance records, some of which pertained regardless of its engine type.the

Vauxhall’s ‘T Car’ Chevette appears in the UK as a 2 or 4 door saloon (sedan).

1977

Michael Edwardes takes over the helm of the British Leyland conglomerate, together with its labour relations, production quality and public perception .

Volkswagen cease production of the ‘Beetle’ in Germany forty years after production began.

Rover’s 3500 ‘SD1’ wins the European Car of the Year award.

Merger plans between Swedish manufacturers Saab and Volvo are abandoned.

Production of the Wankel rotary engined NSU Ro80 comes to an end.

Porsche introduce 924 and 928 models, both featuring front-mounted water-cooled engines and rear transaxles. The 924 is an aborted VW project and thus contains a high percentage of WV parts-bin components, including the engine from the Transporter van. The V8 powered 928 is eventually intended to take over from the 911 and wins the European Car of The Year Award.

1978

The Volvo DAF conglomerate slips into financial difficulties. The Dutch Government comes to the rescue with financial aid.

British Leyland shows substantial signs of recovery in the hands of Michael Edwardes but the company’s future is far from secure.

Toyo Kogyo launch the Mazda RX7, a two-seat sports coupe powered by a Wankel rotary engine.

Ford introduces the Fiesta, their first front-wheel-drive small family car. It is to be made at plants in England, Spain and Germany.

1979

Rolls Royce Motor Company is sold to Vickers for £38m as part of the Rolls-Royce engineering group.

Rover begins collaboration with Honda.

Maserati Bora production comes to an end.

Simca- Matra complete the first model of new and practical concept in personal transportation. Based on a single-box van-like shape but with a car-like interior and comfortable flexible seating for up to seven people, the P17 concept is rejected by Talbot-Simca, prompting Matra to approach Renault and to develop the concept further in prototype P18. The MPV is on its way!

1980

Rear wheel drive Escort Mk2 production comes to an end to make way for the new front-wheel-drive Escort Mk3.

Bitter strikes at British Leyland provoke chairman Sir Michael Edwardes to threaten "Return to work or lose your jobs."

Daimler-Jaguar division of British Leyland gets John Egan as its new Chairman. Egan sets about rebuilding pride in the quality of design and production, lost since British Leyland’s formation.

1981

General Motors announces the launch of the Saturn project in the USA, with the intention of creating a new brand and new products from scratch.

John Z DeLorean, former General Motors high-flyer, launches the DMC-12, his stainless steel gull-wing dream car into a world of recession and high interest rates. Designed by Georgetto Guigaro, engineered by Lotus Cars and powered by the Douvrin PRV V6 engine it appears over-priced against stiff opposition and quality issues compound the problem.

Maserati launch the Biturbo range of coupes, spyders and saloons powered by twin-turbocharged all-alloy V6 engines.

1982

Honda starts production at its first US factory.

Having built 8,563 DMC-12s, the DeLorean Motor Company’s factory in Northern Ireland goes into receivership and after a few months, the British government, DeLorean’s biggest creditor by far, issues orders to shut it down.

Anthony Colin Bruce Chapman dies suddenly aged 54, having grown Lotus into an extraordinarily successful Grand Prix team, a substantial low-volume sports car production specialist and an extremely reputable auto-engineering consultancy.

1983

Lexus is announced as the name of Toyota’s new luxury brand in the USA and Europe, intended to allow them to overcome brand prejudice and compete head to head with the prestige European and American manufacturers.

Maserati end production of the Merak

1984

Japanese manufacturer Toyo Kogyo changes its name to Mazda Motor Corporation.

Renault release the new Espace, the first MPV, designed, developed and built for them by Matra at their assembly plant in Romorontin, near Paris.

1985

Chrysler buys AMC and takes over production of the Jeep range.

Founder of Jaguar, Sir William Lyons, dies as the company sees its reputation for quality and value return.

1986

Volkswagen takes a 51% share in Spanish car makers SEAT.

1987

The Ford Motor Company acquires a 75% shareholding in Aston Martin Lagonda.

1988

The new Lincoln Continental is Ford’s first car with a six-cylinder engine and front-wheel drive.

Fiat acquires additional shares in Ferrari, taking its total shareholding to 90%.

Enzo Ferrari dies in Modena, aged 90.

British Aerospace buys Rover Group.

1989

General Motors takes a 50% stake in Saab of Sweden.

General Motors introduces the Geo brand to market Suzuki, Isuzu, and Toyota models in the USA.

Lexus introduces its first model, the LS400.

Honda announces plans to establish European car production by expanding its existing manufacturing facilities at Swindon UK

Honda starts Civic production at its East Liberty, Ohio plant.

Ford takes over Jaguar Cars, promising to build on the unique identity and brand values of the Jaguar name.

1990

Vickers Rolls Royce and BMW announce a joint venture company to build aero-engines – BMW Rolls-Royce GmbH.

Following Czech government approval, VW establishes a new partnership with Skoda.

1992

The Dodge Viper is released with a steel chassis, a glass-fibre body and a 400 horsepower light-alloy V10 engine.

1993

Maserati is bought outright by Fiat.

With development input from parent company Ford, Jaguar announces a vastly improved XJ6.

Sir David Brown, former owner of Aston-Martin Lagonda, dies aged 89.

Aston Martin introduce the DB7, with sleek, modern bodywork, strong six cylinder engines and Jaguar XJS underpinnings. Produced at a dedicated factory in Bloxham, near Banbury in Oxfordshire, it soon begins to achieve sales levels previously unheard of for any Aston Martin.

1994

BMW buys Rover Cars from British Aerospace.

McLaren Cars, previously successful as Formula 1 racing car constructors, introduce the F1 sports supercar. Designed by Gordon Murray and Peter Stevens it features a BMW V12 engine, a top speed well in excess of 200 mph and a price in excess of £500,000.00.

The Ford Motor Company acquires the outstanding 25% interest Aston Martin Lagonda to gain complete control.

1996

The Museum of Modern Art in New York places an early E-Type roadster on permanent display, only the third car to given this honour.

Jaguar introduces the V8 Powered XK8 as a replacement for the venerable XJS.

1997

Vickers put Rolls-Royce Motor Cars up for sale to the highest bidder.

1998

Ferrari takes control of Maserati, and closes the factory for a complete refit and modernisation.

VW announce the New Beetle. A modern stylised interpretation of the original, it shares its floor-pan and many mechanical components with the front-wheel drive Golf.

Rolls Royce is sold after an acrimonious bidding war between Volkswagen and BMW. The final outcome is that, while VW wins the production plant at Crewe and the Bentley brand name, BMW buys the rights to use the Rolls Royce name and announces its plan to develop a new generation of cars which will be built at its own British factory from 2003.

Chrysler and Daimler Benz merge to form Daimler-Chrysler. Initial indications are that the two businesses will remain autonomous.

1999

Volvo sells its car-making division to Ford Motor Company but continues to manufacture trucks.

Aston Martin becomes part of Ford’s Premier Automotive Group joining Jaguar, Lincoln and Volvo, enabling it to call on a pool of expertise, financial and technical resources which would otherwise have been way beyond its reach.

2000

Having invested considerably in the Rover Group and struggled unsuccessfully to make it pay, BMW withdraws and ‘sells’ Rover and MG to The Phoenix Group for a token £1.00. BMW retains the rights to brands Mini, Triumph, Riley and Land Rover, the last of which it then sells to Ford.

2001

Under the ownership of BMW Rolls-Royce move production from Derby to a new, purpose built factory next to the old Grand Prix circuit at Goodwood, West Sussex.

BMW release the ‘NEW MINI’, a modern interpretation of the original Mini built at the former Morris Abingdon plant. Powered by a South-American built, Chrysler-sourced engine, it retains the original’s cheeky appeal and dynamic handling.

In the UK, a new Licence-plate numbering system is introduced.

Jaguar Cars introduce the X Type, based on an extended version of Ford’s European Mondeo floorpan with transverse engine and 4 wheel-drive.

2002

Rolls Royce complete their new factory and commence production of the new Phantom, due for delivery to customers on the 1st January 2003.

Named after the company’s founder Enzo, Ferrari introduce the Enzo supercar. Made of carbonfibre and incorporating much else in the way of Formula 1 technology, its all-alloy, 660 bhp, V12 engine endows the Enzo with a top speed of 217.5 mph.

2003

First customers for Rolls Royce’s New Phantom take delivery on 1st January as promised and world-wide deliveries commence.

Production of the ‘Beetle’ finally comes to an end at VW’s Puebla, plant in Mexico.

Matra’s production-line closes at Romorontin, following commercial failure of Renault’s Avantime and their decision to take Espace production in-house. Matra and its facilities are sold to Italian styling house and niche production specialists Pininfarina SpA, who rename the company Matra Automobile Engineering.

Peter Morgan, son of Morgan founder ‘HFS’ dies aged 84, leaving the business in the safe hands of his son Charles.

Now owned by Volkwagen, Bentley introduces their first all-new design. Based on VW’s large-car platform, the new Continental GT features a contemporary body (styled in-house), 4 wheel drive and an extensively re-engineered version of VW’s 6 litre W12 engine, twin-turbocharged to produce 552bhp.

2004

Car production in the UK reaches its highest level in five years. Britain’s biennial motor show has its last event at the National Exhibition Centre before its move back to London.

More than 40 years after it was launched, the e-type Jaguar has a special exhibition devoted to it at London’s Design Museum.

Production begins on the Aston Martin Volante.

24 year old Russian multimillionaire Nikolas Smolensky purchased Blackpool based TVR for £15 million.

2005

MG Rover -the last "traditional" British mid-sized car manufacturer goes into administration with the key assets finally being purchased by China based Nanjing Automobie Group. Thousands of jobs are lost although there is hope that small scale car manufacturing could return to the same Longbridge plant sometime in the future.

Elsewhere in the Midlands, production begins on the new Aston Martin Vantage.

2006

Honda and the MINI brand continue to help the UK economy as both enjoy increased investment resulting in new jobs. Honda plans to add a further 700 people to its UK workforce, while the world-wide success of the MINI will result in a further 1200 jobs in manufacturing and assorted component industries.

Nissan announce that its new Qashqai car will be built at the company’s Sunderland plant, with the cars being exported across the globe, including Japan. The Qashqai is described as a crossover -effectively a passenger car with a sleek dynamic top half combined with SUV attributes of large pronounced wheel arches and slightly elevated ground clearance. In terms of its size its sits between C-segment hatchbacks and SUVs.

Lotus announces it is to produce a new mid-engined sports car which should be available in about two years time.

The 1½ millionth Honda Civic rolls of the production line at Bridgend.

TVR, the innovative Blackpool based specialist sports car company finally closes its doors after a long battle to remain in production. Owners, enthusiasts and employees meet up for a final celebration in Blackpool.

The British Motor Show returns to London after several decades in the West Midlands. The new venue is the Excel Centre on the banks of the River Thames and nearly 500,000 people attend.

The 30,000th Aston Martin is produced, while the Jaguar XK coupe wins Britain’s car of the year award and luxury car of the year awards.

2007

The Bentley marque enjoys continued success under the parentage of Volkswagen and its newest model is the company’s fastest ever production car -the Bentley Continental GT Speed. It has a top speed of over 200 mph and can get from 0-60 mph in just 4.3 seconds. It is offered for sale in Britain at £137,500.

Manufacturers around the world put more effort and resources into designing and building more environmentally friendly vehicles as the price of oil increases and there is greater awareness of the damage that harmful pollutants are causing from traditional petrol based engined cars.

Britain’s young motor racing star Lewis Hamilton very nearly becomes the new world F1 motor racing champion in his first season -eventually being beaten in the final race. His success though reignites interest in motor sport around the world.

2008

Ford accepts an offer by the rapidly expanding Tata Motors of India for the purchase of Land Rover and Jaguar. The Indian company say their aim is to ensure the cars will remain essentially British.

As the Model T celebrates its 100th anniversary, Ford also announces plans for a year long celebration of the iconic car around the world. One initiative is for a surviving car to be displayed in the "glass tank’ outside the Design Museum in London.

The new Roewe 550 is unveiled at the Shanghai Motor Show in China with the hope that the car may eventually be produced at the old MG Rover plant at Longbridge.

In the US, General Motors announces annual losses for 2007 of billion -the largest ever loss by a US car manufacturer and a further sign that many of the older established car makers are struggling to compete with the surge of production from Asia.

See – History of Motor Car / Automobile Inventions and Improvements

www.flickr.com/photos/brizzlebornandbred/5108328806/