A few nice two shots molds made in china images I found:

Molds

Nice Molds Made In China photos

A few nice molds made in china images I found:

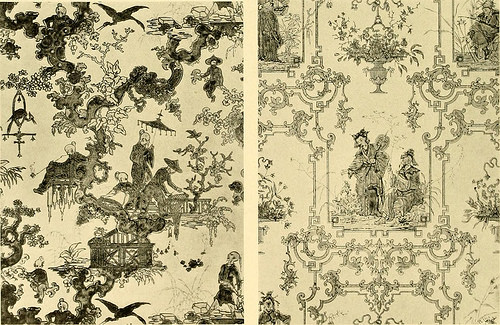

Image from page 397 of “Decorative textiles; an illustrated book on coverings for furniture, walls and floors, including damasks, brocades and velvets, tapestries, laces, embroideries, chintzes, cretones, drapery and furniture trimmings, wall papers, carp

Image by Internet Archive Book Images

Identifier: decorativetextil00hunt

Title: Decorative textiles; an illustrated book on coverings for furniture, walls and floors, including damasks, brocades and velvets, tapestries, laces, embroideries, chintzes, cretones, drapery and furniture trimmings, wall papers, carpets and rugs, tooled and illuminated leathers

Year: 1918 (1910s)

Authors: Hunter, George Leland, 1867-1927

Subjects: Textile fabrics Textile design Lace and lace making Embroidery Wallpaper Leatherwork Interior decoration Tapestry

Publisher: Philadelphia, London, J. B. Lippincott Company Grand Rapids, The Dean-Hicks Company

Contributing Library: Wellesley College Library

Digitizing Sponsor: Wellesley College Library

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

Text Appearing After Image:

Ilatr ii .i(ii)i.K i ( iiiM.-piuxTF.n zrni.u rri.i!s i nil, ciiim.sk styi.i. ;{i>s WALL PAPERS small figures representing arts and erafts, thirteen slieets with heightof eight feet ten inches and combined width of thirty-seven feet. In1781 a China wall ])aper, glazed, blue ground, made for a roomeighteen feet stinare, with gilt moulding. THP: FOI.l.OT fOl.I.ECTIOX The most interesting exhibition eer made of ancient wall paperswas by the late Felix FoUot at the Paris Exposition of 1900. Thewriter was fortunate enough to have lent him a cojn* of the ])rivatelyjn-inted little book jn-epared by M. Follot with the title Papierspeints, a Iexjjosition universelle internationale de 1900. At thisjjoint it is important to note that the French name for wall 2)apers isstill papiers pcinf.s (painted 2)apers), inherited from the })eriod whenthey actually were painted. M. Follot had spent forty years in getting together his collec-tion, and the honour of organising the exhibition was only

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Then and Now® Bathing Suit Barbie® – Made in China

Image by Dolls ‘n Stuff

This version of Then and Now® Bathing Suit Barbie® was made in China. Click here to see one of the versions that was made in Indonesia.

Nice China Molds Make Maker photos

A few nice china molds make maker images I found:

FOR SALE: Original North Light Cob

Image by appaIoosa

Model # P1162 – red roan

Size: 7"H x 8"L

original mold, produced by North Light.

Identifying marks & logos:

Inside hind leg: "© NL 93", plus " MADE IN UK "

"Cob" is a British term for a "cobby" (translation = stout & compact build) horse of undetermined breeding. The Cob is a type rather than a breed. A short-legged horse exceeding 148cms (58 inches or 14.2 hands) with a maximum height of 155cms (61 inches or 15.1 hands). The Cob has bone and substance with quality and is capable of carrying a substantial weight. Cobs should have sensible heads, (sometimes roman nosed), a full generous eye, shapely neck crested on the top, with a hogged mane and well defined wither. The Cob should also have clean, strong hocks and all the attributes of a good hunter.

|||****************************|||

North Light model horse figurines are made of a porcelain and resin composition, which allow for the extensive mold detailing (some with individual hair detailing, braided manes & tails, etc) that is very evident in the finish. The figurines are finished in a studio where they are airbrushed with the body color and shading required for the particular breed piece. Next comes the hand detailing , which can be extensive, depending on the horses’ color pattern. Pinto and appaloosa patterns require extensive hand work, and vary greatly from horse to horse. Facial features also receive hand detailing, with expressive, lifelike eyes which have a final gloss application to make them look moist and realistic. Touches of pink are added to muzzles. Nostrils are darkened inside to add depth.

With this degree of hand detailing, each model horse will vary slightly.

North Light is a company located in Stoke-On-Trent, Staffordshire, England. The area is famous for its potteries and figurines, including the well known Wedgwood, Beswick and Royal Doulton brands. In 2005, the North Light factory was sold – including all existing North Light molds – to the company: WADE CERAMICS LTD (yes, the same company that made those little whimsy figurines found in red rose tea boxes years ago). Wade repackaged the existing North Light horses under their new trademark and resold them within the Wade division as "North Light @ Wade" horses.

Directly from Wade Co. website, verbatim:

———————————–

Contributed by Carol Atrak

Monday, 18 July 2005

We have pleasure in announcing that Wade has purchased certain assets from Dennis Doyle of the North Light resin figurine range. North Light, which will trade as a division within Wade as "North Light @ Wade", is famous for its range of dogs, farm animals, horses and wildlife figurines. They are manufactured in resin and hand painted. The "Classic Dog and Horse Ranges" are finished in marble, china blue, bronze, Monet and other effects to grace the sideboards and coffee tables of the World’s finest homes.

Managing Director, Paul Farmer said, "North Light @ Wade" will bring a new dimension to Wade’s figurine capability and Wade’s mechanisms for online purchases of its ceramic products will be adapted to cater for North Light products too. We are also looking forward to improving our ceramic hand painting techniques which come with the North Light asset purchase."

Artists, Guy Pocock and Anne Godfrey, have been retained to continue modelling new lines and Clare Beswick, from that famous family of figurine makers which bears her name, has been appointed Sales and Product Manager for North Light @ Wade.

The manufacture has been moved from Biddulph to a separate resin area within Wade’s Royal Victoria Pottery in Burslem.

In 2008, Wade announced they would no longer produce the North Light @Wade horses (and dogs) at the factory (in the UK). Instead they decided to release a new line: "North Light @ Wade Premier Collection" (consisting of 17 horses and 22 dogs) – to be produced in China. Many of the existing NL horses you see being sold on eBay (and elsewhere) today, bear the "made in China" sticker, along with the NL backstamp.

In 2009, Wade ceased production altogether on all existing North Light models . Today, North Light horses are no longer being produced, sold or marketed by Wade Ceramics, making these horses highly sought after, valuable and rare.

I have no idea what the Wade Co. decided to do with all the existing North Light horses. Some say they sold the existing molds to a company in China.

If your North Light horse has the "©North Light Made in the UK" backstamp, you have a very rare & valuable collectible indeed!

The Greek Slave, Victoria and Albert Museum, London. Fujifilm.

Image by scotbot

Minton’s version of the Greek Slave was first produced in 1848. It is made of Parian, Minton’s name for statuary porcelain, which alludes to the white marble from the Greek isle, Paros. The figure copied a marble statue first exhibited in London in 1845 and now in Raby Castle, Durham. A marble replica, now in the Corcoran Gallery, Washington DC, was shown at the Great Exhibition. It stood against a red plush backdrop in the main avenue of the Crystal Palace and was much admired, despite ambivalent Victorian attitudes to displayed nudity.

Materials & Making

At the Exhibition of 1851, Minton’s trade name, Parian was in general use for all vitrified unglazed bone china, even though rival companies had invented their own names for the material. Each part of a figure was made in a separate mould. The smooth appearance of the finished figure was admired as much for its technical skill as for its aesthetic qualities. Minton produced over 500 Parian figures between 1845 and 1910.

People

The American sculptor, Hiram Powers (1805-1873) was the son of a Vermont farmer who was fortunate to receive help from a patron to move to Florence in 1837, where he established his reputation.

Subjects Depicted

Hiram Powers’ Greek Slave depicts a Greek woman exposed for sale at a Turkish bazaar. It alludes to the Greek War of Independence (1821-1832) but was also topical as slavery was abolished in Britain in 1833, while it was still prevalent in many American states. Minton later produced further slave figures, including an American Slave in 1862.

Date

1862 (made)

Artist/maker

Powers, Hiram, born 1805 – died 1873 (after, sculptor)

Minton, Hollins & Co. (maker)

Materials and Techniques

Parian porcelain

Dimensions

Height: 35.4 cm, Width: 11.3 cm, Depth: 9.9 cm

Object history note

Made by Minton & Co., Stoke-on-Trent, Staffordshire

Descriptive line

The Greek slave

Labels and date

British Galleries:

The full-scale marble sculpture of ‘The Greek Slave’, carved by the American sculptor Hiram Powers (1805-1873) in 1843, was one of the most popular exhibits at the Crystal Palace in 1851. This is a small scale version made in Parian porcelain. The invention of a machine in 1844 which could reduce sculptural works in scale meant that Parian replicas could be produced with a high degree of accuracy. [27/03/2003]

Production Note

Mould dated 1848; this example made in 1862

Cool China Molds Make Maker images

Check out these china molds make maker images:

Vintage Milk Glass Salt and Pepper Shakers with Flower Power 70s Silkscreen

Image by GranniesKitchen

This set of vintage milk glass salt and pepper shakers are decorated with a green and orange flower power silkscreen.

The glass maker’s mark on the bottom indicate they were made by the Dominion Glass Company at their Wallaceburg factory in either January of February of 1977. The mould model number is 1632.

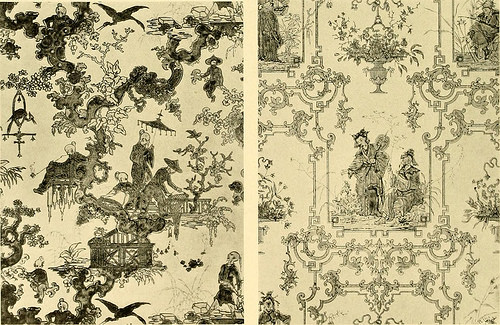

Spread the Word! – Save Jobs.

Image by Hasenpfeffer Incorporated

We make and sells dolls, teddy bears, and such. But this isn’t a plug for our business. As a reaction to the dangerous-toy scare last year, the Consumer Product Safety Commission created something called the Consumer Products Safety Improvement Act. It requires all manufacturers of children’s goods to submit their products for testing for lead and phthalates.

While that’s good in the overall scheme, it has some potentially damaging side effects. The problem is that the average testing fee runs a few thousand dollars. Making matters worse, we would have to submit each and every toy for testing since no two are alike (she makes her stuff from salvaged materials like old wool coats and such). Naturally you can see what this version of the act would do to the handmade toy and craft industry (it’s more than macramé owls nowadays).

There is a potential remedy, though. Below is the unabridged copy from the Handmade Handmade Toy Alliance. Below are links to a sample letter and to various legislators.

Save the USA from the CPSIA

In 2007, large toy manufacturers who outsource their production to China and other developing countries violated the public’s trust. They were selling toys with dangerously high lead content, toys with unsafe small part, toys with improperly secured and easily swallowed small magnets, and toys made from chemicals that made kids sick. Almost every problem toy in 2007 was made in China.

The United States Congress rightly recognized that the Consumer Products Safety Commission (CPSC) lacked the authority and staffing to prevent dangerous toys from being imported into the US. So it passed the Consumer Product Safety Improvement Act (CPSIA) in August, 2008. Among other things, the CPSIA bans lead and phthalates in toys, mandates third-party testing and certification for all toys and requires toy makers to permanently label each toy with a date and batch number.

All of these changes will be fairly easy for large, multinational toy manufacturers to comply with. Large manufacturers who make thousands of units of each toy have very little incremental cost to pay for testing and update their molds to include batch labels.

For small American, Canadian, and European toymakers, however, the costs of mandatroy testing will likely drive them out of business.

* A toymaker, for example, who makes wooden cars in his garage in Maine to supplement his income cannot afford the ,000 fee per toy that testing labs are charging to assure compliance with the CPSIA.

* A work at home mom in Minnesota who makes dolls to sell at craft fairs must choose either to violate the law or cease operations.

* A small toy retailer in Vermont who imports wooden toys from Europe, which has long had stringent toy safety standards, must now pay for testing on every toy they import.

* And even the handful of larger toy makers who still employ workers in the United States face increased costs to comply with the CPSIA, even though American-made toys had nothing to do with the toy safety problems of 2007.

The CPSIA simply forgot to exclude the class of toys that have earned and kept the public’s trust: Toys made in the US, Canada, and Europe. The result, unless the law is modified, is that handmade toys will no longer be legal in the US.

If this law had been applied to the food industry, every farmers market in the country would be forced to close while Kraft and Dole prospered.

How You can Help:

Please write to your United States Congress Person and Senator to request changes in the CPSIA to save handmade toys. Use our sample letter or write your own. You can find your Congress Person here and Senator here.

Thank you so much!

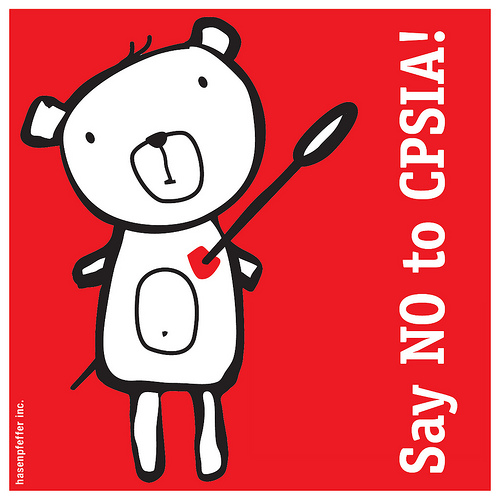

FOR SALE: Original North Light “Kitley Ladybird” – Dartmoor Pony mare

Image by appaIoosa

Model # P1133 – bay

Size: 5-3/4"H x 6-1/2"L

Original mold, produced by North Light.

Identifying marks & logos:

On belly: "KITLEY LADYBIRD "

On right buttock cheek: " © North Light 1986 "

Inside right hind leg: " Godfrey "

Inside left hind leg: " MADE IN UK

This is a model of the classic British breed, the Dartmoor. These ponies are hardy and well balanced, originating in Devon, England. This breed is closely related to the Exmoor Pony and probably descended from the same stock. These ponies roamed wild over the rugged moorlands of southwestern Devon for many centuries. Toward the end of the 19th century, the breed’s traits were stabilized by the creation of the Dartmoor Pony Breed Society, with standard requirements. The maximum height for this pony is 12.2 hands high at the withers. She is a well-balanced pony with small head, ears and eyes. The mane and tail are thick and full. The neck is wide, the chest deep and muscular and the shoulders are strong and sloping.

This North Light model is a lovely representative of a Dartmoor Pony from the North Light Native Pony Series.

|||****************************|||

North Light model horse figurines are made of a porcelain and resin composition, which allow for the extensive mold detailing (some with individual hair detailing, braided manes & tails, etc) that is very evident in the finish. The figurines are finished in a studio where they are airbrushed with the body color and shading required for the particular breed piece. Next comes the hand detailing , which can be extensive, depending on the horses’ color pattern. Pinto and appaloosa patterns require extensive hand work, and vary greatly from horse to horse. Facial features also receive hand detailing, with expressive, lifelike eyes which have a final gloss application to make them look moist and realistic. Touches of pink are added to muzzles. Nostrils are darkened inside to add depth.

With this degree of hand detailing, each model horse will vary slightly.

North Light is a company located in Stoke-On-Trent, Staffordshire, England. The area is famous for its potteries and figurines, including the well known Wedgwood, Beswick and Royal Doulton brands. In 2005, the North Light factory was sold – including all existing North Light molds – to the company: WADE CERAMICS LTD (yes, the same company that made those little whimsy figurines found in red rose tea boxes years ago). Wade repackaged the existing North Light horses under their new trademark and resold them within the Wade division as "North Light @ Wade" horses.

Directly from Wade Co. website, verbatim:

———————————–

Contributed by Carol Atrak

Monday, 18 July 2005

We have pleasure in announcing that Wade has purchased certain assets from Dennis Doyle of the North Light resin figurine range. North Light, which will trade as a division within Wade as "North Light @ Wade", is famous for its range of dogs, farm animals, horses and wildlife figurines. They are manufactured in resin and hand painted. The "Classic Dog and Horse Ranges" are finished in marble, china blue, bronze, Monet and other effects to grace the sideboards and coffee tables of the World’s finest homes.

Managing Director, Paul Farmer said, "North Light @ Wade" will bring a new dimension to Wade’s figurine capability and Wade’s mechanisms for online purchases of its ceramic products will be adapted to cater for North Light products too. We are also looking forward to improving our ceramic hand painting techniques which come with the North Light asset purchase."

Artists, Guy Pocock and Anne Godfrey, have been retained to continue modelling new lines and Clare Beswick, from that famous family of figurine makers which bears her name, has been appointed Sales and Product Manager for North Light @ Wade.

The manufacture has been moved from Biddulph to a separate resin area within Wade’s Royal Victoria Pottery in Burslem.

In 2008, Wade announced they would no longer produce the North Light @Wade horses (and dogs) at the factory (in the UK). Instead they decided to release a new line: "North Light @ Wade Premier Collection" (consisting of 17 horses and 22 dogs) – to be produced in China. Many of the existing NL horses you see being sold on eBay (and elsewhere) today, bear the "made in China" sticker, along with the NL backstamp.

In 2009, Wade ceased production altogether on all existing North Light models . Today, North Light horses are no longer being produced, sold or marketed by Wade Ceramics, making these horses highly sought after, valuable and rare.

I have no idea what the Wade Co. decided to do with all the existing North Light horses. Some say they sold the existing molds to a company in China.

If your North Light horse has the "©North Light Made in the UK" backstamp, you have a very rare & valuable collectible indeed!

Nice China Molds Make Maker photos

Check out these china molds make maker images:

Vintage Milk Glass Salt and Pepper Shakers with Flower Power 70s Silkscreen

Image by GranniesKitchen

This set of vintage milk glass salt and pepper shakers are decorated with a green and orange flower power silkscreen.

The glass maker’s mark on the bottom indicate they were made by the Dominion Glass Company at their Wallaceburg factory in either January of February of 1977. The mould model number is 1632.

Cool China Molds Produce images

Check out these china molds produce images:

Image from page 60 of “Staffordshire pottery and its history” (1913)

Image by Internet Archive Book Images

Identifier: staffordshirepot00wedg

Title: Staffordshire pottery and its history

Year: 1913 (1910s)

Authors: Wedgwood, Josiah C. (Josiah Clement), 1872-1943

Subjects: Staffordshire pottery Potters Wedgwood ware

Publisher: London : S. Low, Marston & co. ltd.

Contributing Library: Robarts – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

the lathe after throw-ing, and thus made thin and light. The claybody is homogeneous and smooth, showinggreater care in the preparation of the body.The ornamentation is delicate and artistic,and has been made by sealing a soft piece ofthe clay on to the ware with a metal sealpressed over the soft clay. There is no glaze,but a high fire has produced a ware so hard as tobe almost forged solid. These things show thehand of the ex-silversmith in size and shape andfinish. The Burslem imitators—Garner and theWedgwoods—never made things like these. Elers,though he may have stolen Dwights secrets, wentahead and showed the possibilities of potting. Heis said also to have produced black ware of asimilar character by mixing oxide of man-ganese—the magnus of Dr Plot—with theclay body, and, though no known pieces ofblack Elers ware can now be certainly identified, 36 Q^/N^p i. Red china teapot, probably by Elers. c. 1700.2. Sample of later date, with moulded spout. Stoke-on-Trent Museums.

Text Appearing After Image:

Samples of solid agate ware made by Wedgwood or Whieldon. c. 1760. From the Stoke-on-Trent Museums (see p. 74). To face p. 36 ELERS AND ART it is this black ware that his copyists chieflydeveloped.* For Nemesis overtook John Philip Elers, andin spite of all his secrecy, perhaps because of it,he was copied. Two potters, Twyford and Ast-bury,f one of whom at least had already made potsafter local methods in Shelton, set themselves in-dependently to acquire the arts of the Dutchman.To lull the suspicions of Elers, Twyford shammedstupidity, and Astbury, who was younger, passedhimself off as an idiot. Recommended by thesestrange qualifications, they asked and obtainedemployment and, in time, the knowledge theydesired. They went back to Shelton with theiracquired arts, and, in a few years, the most in-telligent potters of North Staffordshire knew howto make civilized pottery. But by 1710 JohnPhilip Elers was tired of his exile and of the * Burton, English Earthenware, p. 74. t A list of tho

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Nice Two Shots Molds Created In China photos

Verify out these two shots molds produced in china images:

Steven F. Udvar-Hazy Center: South hangar panorama, including Vought OS2U-three Kingfisher seaplane, B-29 Enola Gay

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Vought OS2U-3 Kingfisher:

The Kingfisher was the U.S. Navy’s principal ship-based, scout and observation aircraft throughout Planet War II. Revolutionary spot welding strategies gave it a smooth, non-buckling fuselage structure. Deflector plate flaps that hung from the wing’s trailing edge and spoiler-augmented ailerons functioned like added flaps to permit slower landing speeds. Most OS2Us operated in the Pacific, where they rescued many downed airmen, including Planet War I ace Eddie Rickenbacker and the crew of his B-17 Flying Fortress.

In March 1942, this airplane was assigned to the battleship USS Indiana. It later underwent a six-month overhaul in California, returned to Pearl Harbor, and rejoined the Indiana in March 1944. Lt. j.g. Rollin M. Batten Jr. was awarded the Navy Cross for making a daring rescue in this airplane beneath heavy enemy fire on July 4, 1944.

Transferred from the United States Navy.

Manufacturer:

Vought-Sikorsky Aircraft Division

Date:

1937

Country of Origin:

United States of America

Dimensions:

Overall: 15ft 1 1/8in. x 33ft 9 1/2in., 4122.6lb., 36ft 1 1/16in. (460 x 1030cm, 1870kg, 1100cm)

Components:

Wings covered with fabric aft of the main spar

Physical Description:

Two-seat monoplane, deflector plate flaps hung from the trailing edge of the wing, ailerons drooped at low airspeeds to function like added flaps, spoilers.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of World War II and the 1st bomber to home its crew in pressurized compartments. Although designed to fight in the European theater, the B-29 found its niche on the other side of the globe. In the Pacific, B-29s delivered a variety of aerial weapons: standard bombs, incendiary bombs, mines, and two nuclear weapons.

On August six, 1945, this Martin-constructed B-29-45-MO dropped the first atomic weapon employed in combat on Hiroshima, Japan. Three days later, Bockscar (on show at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance climate reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on each missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

General: 900 x 3020cm, 32580kg, 4300cm (29ft 6 five/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Supplies:

Polished overall aluminum finish

Physical Description:

4-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish general, normal late-World War II Army Air Forces insignia on wings and aft fuselage and serial quantity on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on reduced left nose.

Cool Precision Molds Created In China pictures

Some cool precision molds produced in china images:

Steven F. Udvar-Hazy Center: View of south hangar, which includes B-29 Superfortress “Enola Gay”, a glimpse of the Air France Concorde, and several other individuals

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of Planet War II and the 1st bomber to home its crew in pressurized compartments. Although created to fight in the European theater, the B-29 identified its niche on the other side of the globe. In the Pacific, B-29s delivered a range of aerial weapons: conventional bombs, incendiary bombs, mines, and two nuclear weapons.

On August six, 1945, this Martin-constructed B-29-45-MO dropped the first atomic weapon employed in combat on Hiroshima, Japan. 3 days later, Bockscar (on show at the U.S. Air Force Museum near Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Wonderful Artiste, flew as an observation aircraft on each missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

General: 900 x 3020cm, 32580kg, 4300cm (29ft 6 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Components:

Polished overall aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and higher-aspect ratio wings. Polished aluminum finish general, common late-Globe War II Army Air Forces insignia on wings and aft fuselage and serial quantity on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on lower left nose.

Plastic molds application and its solution use by contemporary human

Polymers are the ideal invented material by mankind which eased human life to very wonderful extent. Most of the day to day use in human society like tyres, automobiles, bags, packaging, rope and something you name it. Rubber is one of the product of polymer also called as elastomers is employed in creating tyres primarily. Created nations like USA and few western nations are making use of synthetic rubbers for greater impact and ease in manufacturing. The synthetic assortment rubber is also identified as styrene-butadiene rubber (SBR). One more type of polymers are plastics which is consumed at a quantity of 60 billion pounds by nations like USA . China molding solution makes use of thermoplastics and thermosetting types.

Thermoplastics are soft in structure and are effortless to melt and shape according the mold. But, thermosetting kinds have extremely tight structure as there are molecules are bind to each and every other in a complicated form. It can only be melted at an really high temperature and also, this is not as versatile as thermoplastics. Mainly thermoplastics are commercially utilized , as compared to thermosetting types. Every day use application for thermoplastic type material are plastic bags, electrical insulation, packaging, containers , tubes, pipes, caps and bottles. Chinese plastic mold maker use thermoplastic sorts , categorized into an additional two kinds LDPE ( Low Density Polyethylene ) and HDPE ( Higher Density Polyethylene ) primarily based on their cross linking structure. Other kind of extremely difficult and resilient materials are employed from the supplies consist of HMW ( Higher molecular weight polyethylene) and UHMW ( Ultra High Molecular Weight Polyethylene ).

Fibre is also another kind of use of polymers. Man created fiber components incorporate nylon, polyester, rayon and acrylic. These supplies are utilised in clothing, carpets ( as it is a natural insulator ), bullet proof vests . They are really tensile and tough in structure. Plastics are processed and manufactured utilizing methods like injection molding and extrusion molding. Whereas , fibres are processed employing the strategy of spinning. Manufacturing moulds for healthcare molding is really challenging as the silicones employed as raw material has to undergo a lot of regulatory compliance. A bigger profit margin is realized in production than other industrial molding applications. Plastic crates moulds are used to generate HDPE plastic crates of distinct commercial dimensions like 400 x 300 x 160mm, 580 x 375 x 160mm, 600 x 400 x 120mm, 600 x 400 x 200mm ( fish crates ), 500 x 380 x 325mm (vegetable crates ). There are numerous kinds of injection molding solutions available from injection molding manufacturer like Sino Holdings. Services like fast injection molding, low-volume injection molding, proto-duction injection mold tooling and production tools for companies.

Plastic furnishings are manufactured in the exact same approach as other plastic applications. The plastic furnishings molding approach requires rotational or injection or gas assisted injection molding methods for producing various types of furnitures. Hollow plastic furnishings can be created utilizing rotational molding,, solid plastic furniture in a single piece making use of injection molding and higher top quality , light furniture blending different kinds of plastics can be created using gas assisted injection molding approach.

Good Molds Made In China photos

Check out these molds made in china images:

Oh,Inspiring Wind, Make Thy Sweet Music Out of my Hollowness by your Soft Caressing strokes…..

Image by -Reji

Shot at Lal Bagh Gardens, Bangalore, India

Bamboo plants are one particular of the world’s most versatile resources. Bamboo, since of its strength and flexibility, has been employed for hundreds of years as a key building material in nations like Japan and China. But aside from furnishings constructing and architecture, bamboo plants are also used for a wide array of purposes. One particular of the most exciting areas exactly where bamboo is used is in the creation of instruments. Because bamboo is hollow like pipe, it makes for a natural wind instrument, and cultures from all more than the globe have utilised it to their musical benefit.

Wind moving via bamboo forests or thickets tends to make symphony orchestras appear impotent. Wind moving tiny pieces of bamboo to strike against every single other gives joy and peace to these who hear it.

Like grass it grows rapidly and propagates itself if left alone. Like wood it is powerful, grows numerous places and has a lot of, several uses. Offered its way, bamboo will hold hillsides in place against raging waters unleashed from above. Given its way, developing profusely among peoples judged materially poorest on the planet, with out gigantic industries cutting, gathering, processing, transporting it bamboo is right here, waiting to serve. It is right here to shelter, to style tools, to weave baskets, to aid water obey, to give beauty and sounds.

Bamboo is a group of perennial evergreens in the accurate grass family members (Poaceae, subfamily Bambusoideae, tribe Bambuseae). Giant bamboos are the biggest members of the grass family.

In bamboo, as with other grasses, the internodal regions of the plant stem are hollow and the vascular bundles in the cross section are scattered all through the stem rather of in a cylindrical arrangement. The dicotyledonous woody xylem is also absent. The absence of secondary development wood causes the stems of monocots, even of palms and huge bamboos, to be columnar rather than tapering.

Bamboos are also the quickest developing woody plants in the planet. They are capable of growing up to 60 centimeters (24 in.) or a lot more per day due to a special rhizome-dependent technique. However, this astounding development price is hugely dependent on regional soil and climatic conditions.

Bamboos are of notable financial and cultural significance in East Asia and South East Asia where the stems are utilized extensively in every day life as developing components and as a extremely versatile raw product, and the shoots as a food supply.

There are more than 70 genera divided into about 1,450 species] They are located in diverse climates, from cold mountains to hot tropical regions. They happen across East Asia, from 50°N latitude in Sakhalin by means of to Northern Australia, and west to India and the Himalayas.They also take place in sub-Saharan Africa, and in the Americas from the Mid-Atlantic United States south to Argentina and Chile, reaching their southernmost point anyplace, at 47°S latitude. Continental Europe is not recognized to have any native species of bamboo.

Bamboo is the fastest-developing woody plant on Earth it has been measured surging skyward as quickly as 121 cm (48 in) in a 24-hour period,[six] and can also reach maximal development rate exceeding one particular meter (39 inches) per hour for brief periods of time. A lot of prehistoric bamboos exceeded heights of 85 metres (279 ft). Mostly developing in regions of warmer climates during the Cretaceous period, vast fields existed in what is now Asia.

As opposed to trees, all bamboo have the prospective to grow to complete height and girth in a single developing season of 3–4 months. Throughout this initial season, the clump of young shoots grow vertically, with no branching. In the next year, the pulpy wall of each culm gradually dries and hardens. The culm starts to sprout branches and leaves from every single node. In the course of the third year, the culm additional hardens. The shoot is now considered a completely mature culm. Over the next 2–5 years (depending on species), fungus and mould start to type on the outdoors of the culm, which ultimately penetrate and overcome the culm. About five – eight years later (species and climate dependent), the fungal and mold growth trigger the culm to collapse and decay. This brief life indicates culms are ready for harvest and appropriate for use in construction inside 3 – 7 years

Source: Wikipedia, Odysey Leadership Centre.

Molds Left to Gather Dust

Image by Henry Hemming

Or ‘Mouldy Molds and the Saga of Spode’. Spode, when a pre-eminent china maker, saw its factory closed down in 2008. The website now belongs to Stoke council and is falling into disrepair. The molds with which Spode’s greatest wares had been created now accumulate dust in a forgotten shop. Spode, and indeed Stoke, are an remarkable part of our heritage. Some of Spode’s greatest designs are now made by the brand’s owners Portmerion, but basically the fantastic name is all but gone. The Spode factory is an incredible part of our heritage. There is a visitor centre, run by wonderful volunteers – go visit! Spode is in the town of Stoke, one particular of the five towns of Stoke-on-Trent. Taken 19 October 2014. I spent the day touring our pottery past with Pete Taylor (@ForrestGrump), whose significantly more fantastic photographs of the day are a should.